Establishing a Balanced Approach to Odor and Pollutant Issues

Odor and Air Pollutants — A Growing Concern

Odor and air pollutants are areas of continuous concern for the public and an important focus of environmental impact and feasibility studies, capital improvement programs, collection system planning, and wastewater treatment plant design and upgrades.

Our expertise in odor control enables clients to meet these growing demands head on. We can provide a

full range of odor services, from investigations through design, construction, commissioning, testing, performance monitoring, and refurbishment of aging systems.

We are also experienced in design optimization and commissioning of a range of odor control technologies including biotechnology, chemical scrubbers, chemical dosing, activated carbon, and thermal oxidation.

Emissions Sampling and Odor Source Characterization

Odor source sampling includes both odor panel analysis and speciation of specific odor-causing compounds. Odor panel evaluations can be used for dispersion modeling evaluation, while the specific odor-causing compounds are evaluated to confirm that the right odor control technology is selected.

Compliance Strategies and Technology Selection and Design

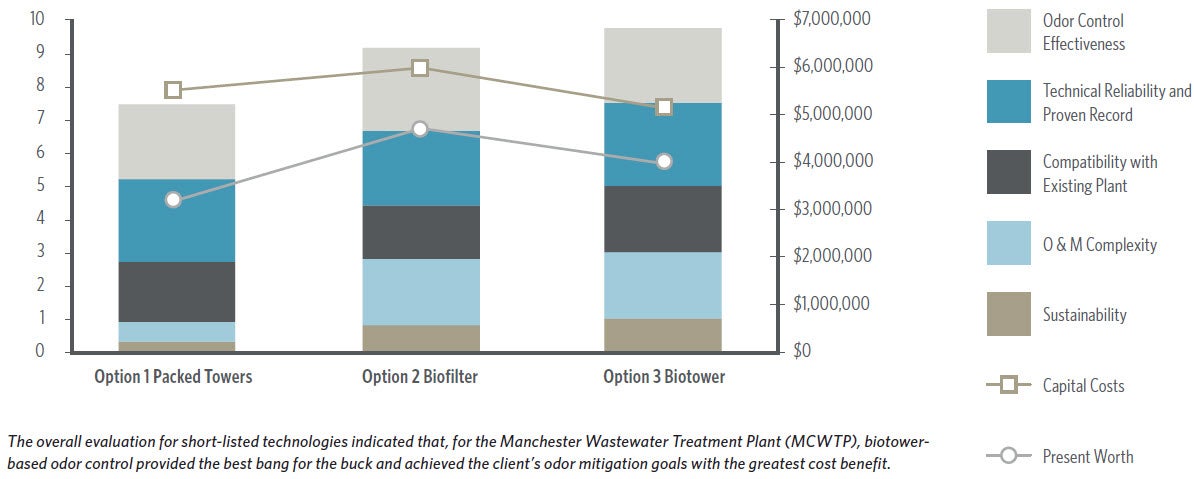

Technology selection processes can be completed to consider both economic and non-economic criteria, utilizing a triple bottom line that follows a multi-criteria evaluation approach to determine the best fit for the plant’s needs. A full range of technologies can be considered and discussed in a Technology Screening workshop format, including:

- Liquid phase odor treatment options

- Gas phase treatment with wet chemical scrubbers

- Gas phase treatment with carbon

- Gas phase treatment with biotowers

- Gas phase treatment with long-life biofilter media systems

- Gas phase treatment with ionization-based systems

A client can select non-economic criteria for a more detailed evaluation of short-listed technology options. Non-economic criteria are defined with the client and may include:

- Odor control effectiveness

- Technical reliability and proven technology

- Compatibility with the existing treatment plant processes

- O&M complexity and safety

- Sustainability

Odor/Air Quality Dispersion Modeling Evaluations

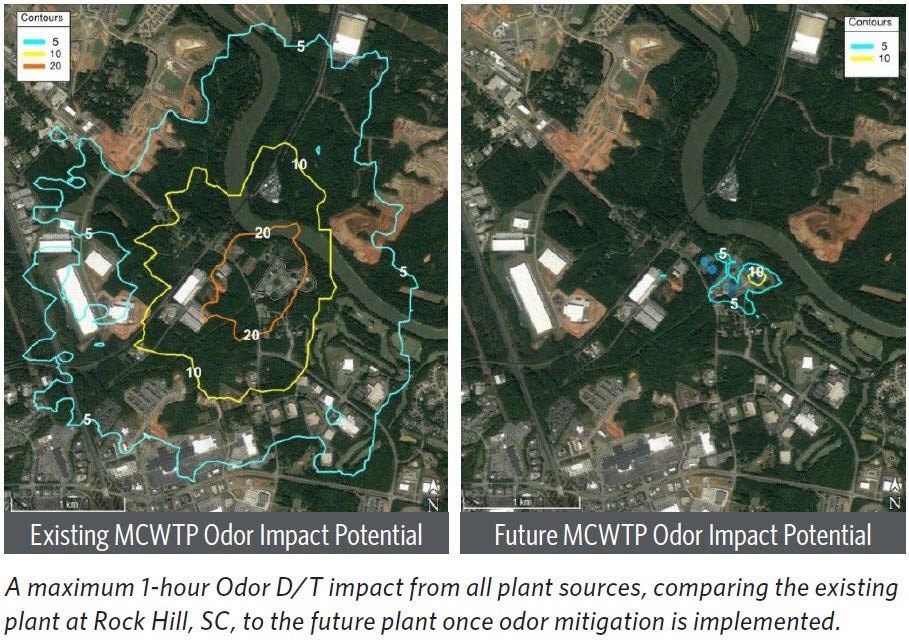

An example using dispersion modeling is the U.S. Environmental Protection Agency’s Office of Air Quality Planning and Standards’ AERMOD dispersion model. This model is often used to determine the baseline odor conditions at a particular plant, which odor sources contributed the most to those odor impact risks, and the reduction in odor footprint once odor mitigation measures were implemented.

Design and Construction of Odor Control Systems

Chemical scrubbers, biofilters, biotowers, carbon adsorption, and other technology options are available.

As an example, the Piscataway Wastewater Treatment Plant is being upgraded to include a new Biosolids Receiving facility and thermal hydrolysis digestion system with related dewatering facilities. The odor control program approach was based on the fact that the existing facility is not receiving odor complaints, and Washington Suburban Sanitary Commission wanted to maintain this “good neighbor” status. Any changes to the existing systems that significantly increase odor emissions were of concern, and any new odor sources will be captured and treated with Best Available Control Technology that fits the site, allowing control of new odor emissions. No new significant odor sources will be added without providing odor containment and scrubbing.

The Piscataway WWTP currently uses lime as a conditioning agent in gravity thickeners to provide solids stabilization before dewatering. The recycle flow from this process is drained back to the head of the plant, which increases the pH of the plant influent. The higher pH tends to suppress hydrogen sulfide (H2S) emissions from the headworks and primary clarifiers. Testing was completed to determine the impact on future H2S and general odor emissions when lime is discontinued after the Thermal Hydrolysis Process systems are placed in service. Although a pH shift of 1 pH point was measured, this evaluation showed minimal impact for odor emissions from existing primary clarifiers, saving the cost of new covers and odor control in these locations. Although there was a net increase in primary clarifier odor, the primary clarifier odor emissions — as measured by both reduced sulfur compound analysis and odor panel analysis — remained very low even after the lime recycle was halted.

A basis of design was completed for a centralized odor control system, and review and treatment of odor from the following locations:

- The gravity thickeners.

- The inlet blending and distribution splitter boxes to the gravity thickeners.

- Cake receiving truck bays.

- Piscataway cake will be blended with the imported cake for treatment in the THP systems. These cake bins will be covered and vented to odor control.

- The pre-dewatering facilities for treating solids before THP will be captured and vented to odor control.

- Post-dewatering systems for THP cake will be vented to odor control. This includes hoods on the post-dewatering belt presses, a day tank, and a floc tank associated with these presses.

- Sidestream treatment will include filtrate equalization tanks. Although this is anticipated to be a relatively low odor source, it may contain elevated ammonia and low-level reduced sulfur odors. Thus it will also be covered and vented to odor control.

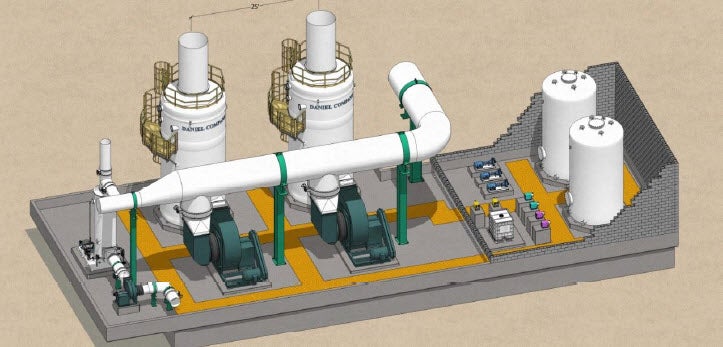

A centralized packed tower chemical scrubber system was designed, providing up to 77,000 cfm of treatment through two parallel caustic/hypochlorite-packed towers under normal operating conditions for all of the above sources, along with 3,700 cfm of pretreatment through an acid scrubber sized for ammonia removal from the THP dewatering sources. Figure 3 shows the scrubber concept.

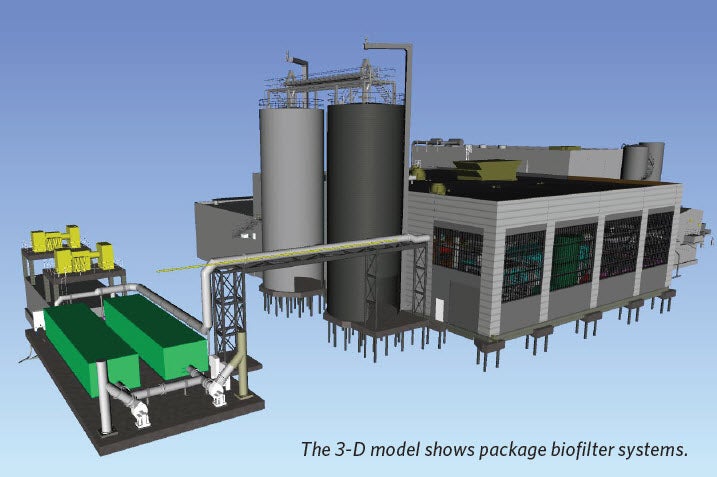

Additionally, as an example where a unique technology was selected, HDR completed preliminary and final design engineering of the new drier and related odor control facilities for the Little Patuxent Water Reclamation Facility in Savage, MD. The project includes new odor control facilities to treat dewatering and drying process air. Odor control options considered in the preliminary engineering stage included chemical scrubbing, carbon adsorption, regenerative thermal oxidizers, and biofilters. Based on observations from drying facility site visits and a qualitative comparison of odor control options, biofilters were selected for odor control for the new dewatering and drying processes for the following reasons:

- Demonstrated success at other belt drying facilities.

- Effective odor control with minimal consumption of chemicals and spent media associated with chemical scrubbers and carbon adsorption systems.

The recommended biofilter odor control system consists of self-contained package biofilters with engineered long-life filter media. Two parallel biofilters, each sized for up to 4,000 cfm, will run continuously to treat odorous air from the dewatering and drier facility. Figure 4 shows a plant view of the concept completed in 3-D modeling. The two package biofilters are located across a plant access roadway from the new drier building, with elevated odorous air ductwork allowing passage of plant truck traffic.

Testing and commissioning and performance evaluation.

- Odor source sampling.

- Odor emissions dispersion modeling to identify high-risk nuisance odor sources.

- Developed odor control master plan recommendations selecting the best technology fit.

- Design of biotower odor control systems to achieve 5 to 10 dilution-to-threshold (D/T) odor compliance goals.

Studies and master planning for new and existing collection systems, pump stations, and wastewater plants.

As an example, HDR worked with a client in South Carolina to complete an Odor Control Master Plan evaluation as part of a large plant upgrade. The OCMP evaluation process included the following steps:

- Reviewing previous odor studies.

- Plant site visit and odor surveys.

- Developing and executing extensive odor source sampling.

- Dispersion modeling, taking into account the type of terrain, the building downwash effects and the weather patterns to evaluate how the odors are carried outside the plant fence line and to better prioritize the true odor sources of concern.

- Developed target odor impact criteria goals to ensure that the plant does not create unacceptable offsite odors that would draw odor complaints from the community.

As concerns around odor and air pollutants grow, the good news is that odor control systems can be blended seamlessly into their environments and can ultimately become community assets. However, as noted, designers and construction personnel need to be aware that not all challenges and solutions work the same. When creating the balance between public and new development, make sure to address odors and their ongoing and long-term impacts early enough so that the community can truly benefit.