Complex Freeway and Bridge Design Built on Proactive Stakeholder Engagement

Innovation and Collaboration Help Illinois’ Mile Long Bridge Project Maintain Traffic, Manage Construction Constraints

By Dan Prokop

In November 2020, the Illinois Tollway opened the new northbound structure of the I-294 Mile Long Bridge Reconstruction and Widening Project. The milestone, reached after 18 months of construction, shows the value of early stakeholder involvement, innovative roadway geometry and in-depth alternatives analysis that identified solutions to keep traffic moving on the critical bridge while reducing impacts on the environment and Tollway users.

The Mile Long Bridge project is part of the $4 billion reconstruction and widening of the Central Tri-State Tollway (I-294) west of Chicago and is the largest project in the Tollway’s $14 billion Move Illinois capital program. The bridge consists of two structures, northbound and southbound, each stretching nearly 5,000 feet. HDR, in partnership with a joint venture design team that includes H.W. Lochner Inc. and Quiqq Engineering, delivered the Phase I and Phase II design services for this immense and complex project.

Following the demolition of the existing northbound structure, the southbound structure will be constructed in its place, in an area constrained on both sides by the new northbound and existing southbound bridges. The alignment was chosen to minimize the impact on Tollway users during construction, in a solution that required careful planning and coordination.

The original bridges, built in 1958, were approaching the end of their useful service life and increasing traffic demands necessitated additional traffic capacity. After completion, each of the new dual structures will carry five lanes and a flex lane to improve traffic flow that can reach up to 150,000 vehicles daily.

Stakeholder Involvement Leads to Collaborative Design Solutions

The Mile Long Bridge is located along of a stretch of permanent easement with a multitude of project stakeholders. The bridges carry traffic over the Illinois Central Railroad, the Illinois and Michigan Canal, the Chicago Sanitary and Ship Canal, the Metropolitan Water Reclamation District, the Des Plaines River, the Forest Preserves of Cook County, the Burlington Northern Santa Fe Willow Springs Intermodal Yard, Santa Fe Drive, and the 75th Street interchange in the Village of Willow Springs. With so many stakeholders, communication and collaboration began early in the planning phase and proved to be crucial to keep the project moving.

Environmental permitting requirements were also significant, and coordination took place with the U.S. Army Corps of Engineers, Illinois Environmental Protection Agency, U.S. Department of Fish and Wildlife Service, Illinois Department of Natural Resources and the Illinois Nature Preserve Commission. The impacts from construction were a major concern and taken into consideration from the time of concept development. The design was conceptualized starting with how the bridge was to be constructed and the team worked backward toward defining the alignment, span configurations and structure type.

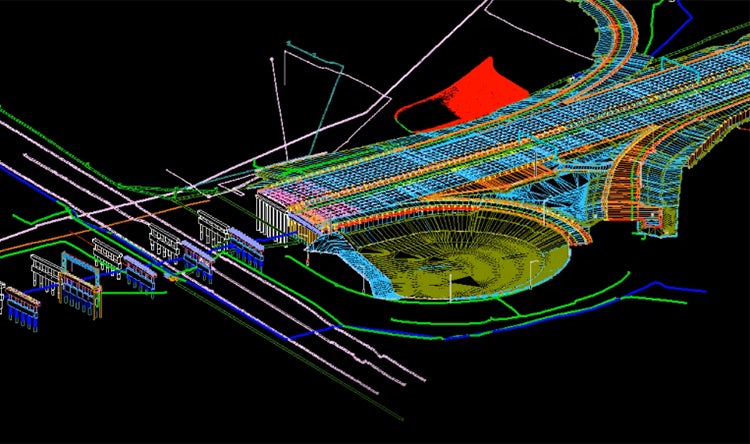

The bridges’ new alignment resulted in utility impacts that also required extensive coordination including two high-voltage ComEd transmission lines that required new towers to raise them prior to construction. Aiding in this effort, building information modeling tools were used extensively for collaboration and for clash detection. This was particularly useful in designing the proposed bridge piers so they did not conflict with existing pipelines and water mains.

Subsurface utility engineering surveys located existing utilities, including a high-pressure jet fuel line that supplied fuel to Chicago’s O’Hare Airport, which was in conflict underneath and along the bridges. During construction, vibration monitoring was performed while the pipeline remained operational, and it was eventually relocated to avoid conflicts.

Designing for Durability

A key element of the bridge’s design was fewer and longer spans, reducing the impact on the waterways and areas below as well as the tollway users during construction. The original dual structures were comprised of 16 units made up of 54 spans. The new bridges were designed with 27 spans, half as many. Reducing the number of spans also meant reducing the number of deck joints, which enhances the durability of the bridge and reduces long-term maintenance and future inspection demands. This project represents a significant infrastructure investment and provisions were taken to maximize the life of these structures. In addition to minimizing the number of deck joints, stainless steel reinforcement was used in the bridge deck, parapets and pier caps under the deck joints for increased durability.

The proposed span lengths were driven by the need to accommodate the railroads’ current and future plans, as well as the desire to span the CSS canal in order to locate piers out of the waterway. To achieve the longer span lengths, steel plate girders were used for the first five spans from the south and unique prestressed concrete beams were used for the northern 22 spans.

The maximum steel span length is 410 feet, and weathering steel plate girders for the south spans met the long span strength requirements and eliminated future bridge repainting needs. The maximum span length in the prestressed concrete spans is 188 feet. A unique beam design was developed for this project, based on the California wide flange beam shape. Ninety inches deep, it includes 48 high-strength steel strands along with 10ksi compressive strength concrete. This represents the longest precast concrete beam ever fabricated, transported and erected in the Midwest.

Construction Staging that Keeps Traffic Moving

Keeping all lanes of existing traffic open during construction was a key priority for the Tollway and its customers. HDR developed and analyzed multiple alternative alignments to find a solution while minimizing impacts to right of way and stakeholders. Ultimately an offset alignment was chosen that allowed the new northbound structure to be built alongside the existing northbound bridge.

While this solution reduced impacts to existing travel lanes, it provided new complexities. At the south end of the Mile Long Bridge, the existing bridge is sharply curved for the last 630 feet of structure. About 900 feet further south, a separate bridge over a major road is also within the same horizontal curve. Keeping all lanes of traffic open meant a complex construction staging and maintenance of traffic effort.

As HDR’s project engineer Dan Prokop explained: “We crisscrossed the existing roadway with proposed geometry changing from an offset of 175 feet north to 45 feet south, in the middle of an existing curve and proposed curve, in between two bridges that are only 900 feet apart, while also raising the proposed grade by 5-8 feet, and did so keeping all lanes of traffic open. It also created space for the main bridge to be poured without longitudinal joints and for both structures to avoid using curved members.”

The complicated maintenance of traffic work involved a temporary median bridge connection, temporary retaining walls, intricate analysis of barrier placement and sight distance analysis, staggered bridge deck removal, and a lot of temporary pavement, including overlay on the existing southbound Mile Long Bridge shoulder to allow the space to be used for traffic.

The result was reduced impacts to existing travel lanes and improved driver expectancy and safety through the work zone, with long term traffic patterns. It also meant less shifting of traffic devices and resulted in a low maintenance of traffic cost of around 0.75% of the project total, which usually averages around 3% for the area.

Success Built on Early Collaboration

In order to achieve the success of a large project like this, it was critical for the design team to identify the geometric and site constraints early on, understand the Tollway’s priorities, define design criteria, and keep close communication and collaboration with the Tollway, the Tollway’s consultants and impacted stakeholders during planning and through the design development.

About the Authors

Dan Prokop. A senior transportation engineer/project manager, Dan has worked on highway projects of all sizes, including many of HDR’s first BIM deliverable projects. He is serving as HDR’s project engineer on the Mile Long Bridge project.