Experts Talk: 3D Design and Deliverables with Will Sharp

Experts Talk is an interview series with technical leaders from across our transportation program.

Staying Ahead of the Transportation Industry's BIM Design Revolution

3D design tools are fundamentally changing the development of transportation projects by reducing conflicts and finding new efficiencies. The technology is already becoming common in some states and will impact stakeholders from state agencies to municipalities to contractors as it continues to gain ground. Contractual 3D deliverables go a step further, using 3D models as the binding legal deliverable for horizontal projects rather than traditional 2D plans.

As organisations and agencies confront this change, HDR is proactively leading several projects to advance the technology and adoption of 3D deliverables, including the national AASHTO BIM for Bridges and Structures five-year pooled fund study. This collaborative effort of more than 20 state DOTs, the Federal Highway Administration and the AASHTO Committee on Bridges and Structures is developing an open, national standard for the exchange of information necessary for the design, fabrication and construction of bridges and structures in the United States.

Will Sharp, HDR’s highways director, is on the front line of this advancing new technology. Sharp has been doing 3D modeling for airports, dams and highway projects since the late ‘80s. More recently, he’s concentrated on national efforts on BIM for Infrastructure, including work with AASHTO and the Transportation Research Board’s BIM for Infrastructure Subcommittee. He’s also been named to the National BIM Program Steering Committee of the National Institute of Building Sciences.

3D Design and Deliverables

Q. When did you first see 3D tech appear and how has it changed over time?

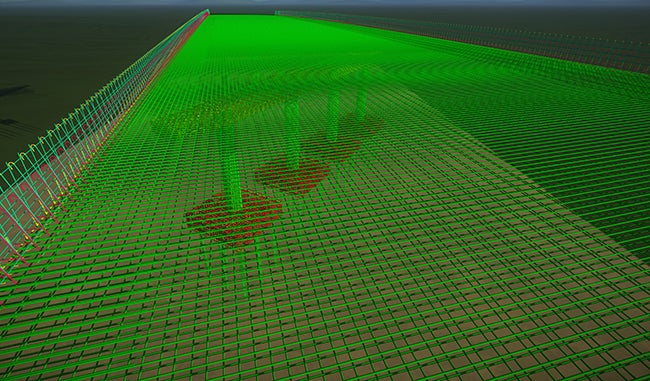

One of my first projects at HDR, over 30 years ago, was modeling runways and building pads for several alternatives being considered for the new Denver International Airport Master Plan. Our approach has greatly changed over time. I would say that we put more effort into it now, but we're also getting a lot more out of the 3D tools that we're using. Thirty years ago, we used it mostly to automate the design plans, and we had limited benefits from the data. Now, we’re able to provide construction level accuracy deliverables that contractors can build from, including the data needed for Automated Machine Guidance grading and paving.

It used to be, “How do I make a model?” Now, it’s “How do I attribute a model” and “How can I use those attributes to do something more powerful?” Fundamental changes in the technology have taken place in recent years. Software tools that are common within the public workspace are updating their parametric capabilities and people are starting to realise the same advantages that maybe other market sectors have seen before.

From the national standpoint, I definitely see this trending with the DOTs and major transportation agencies. These public agencies are moving well beyond conventional design deliverables towards a contractual signed and sealed 3D model, which will eventually replace the traditional 2D plan sheets. Five major transportation agencies, including four state DOTs and the Illinois Tollway, have ongoing pilot projects with signed and sealed 3D contractual deliverables for construction. HDR has been fortunate to be the engineer of record or construction inspector for many of these early pilot projects, including a variety of bridge and roadway designs.

Q. What tasks do you think 3D design makes easier? What applications might we see in the future?

Any task that requires structured information. And that is what we see coming in the future: not only the ability to more easily transmit our data from one source to another, but the ability to better analyse that information. Then we can provide owners the ability to make data-driven decisions based on all that information that they never would have had before.

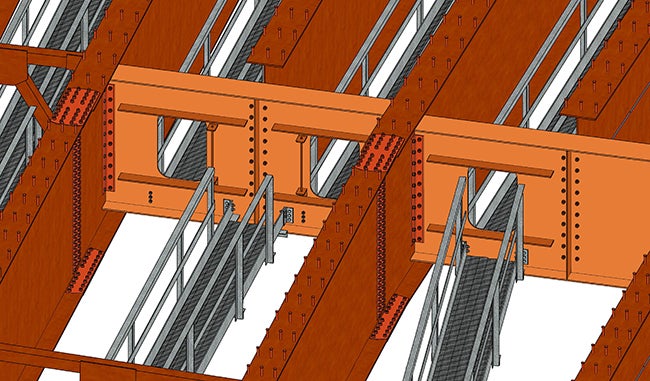

Reducing conflicts between disciplines is a big advantage. Typically with a major transportation project you have roadway engineers designing the horizontal and vertical alignments, the bridge engineers designing the structural elements, the traffic engineers designing traffic signals and signing, the geotechnical engineers looking at slope designs and foundations, and the drainage engineers handling hydraulics and overall drainage. So there's a lot of different disciplines concurrently working on different components of the design.

When not managed well, that can lead to cross-disciplinary misunderstandings or conflicts. But 3D models and technology are getting far enough along that each discipline can now develop its own 3D model, and we can pull them together into a federated model to see all the different disciplines together in a single model. From that federated model, we can do automated interdisciplinary coordination checks and clash detection. It just gives us a much better understanding of the constructability of the design, resolving issues before the project is let.

Q. Going beyond design, what benefits do signed and sealed 3D deliverables add to a project?

The primary drivers in the transportation industry are reduced overall project costs due to improved constructability and reduced change orders in the field. Requiring a 3D deliverable means the benefits discussed earlier are built into the process, and we also have seen improved construction efficiency, with contractors being able to more fully leverage the digital data developed during the design process.

Design efficiency is also notable. Developing the model so it can be utilised as the controlling document requires more initial effort to make the model more comprehensive, but it saves time by eliminating the need for producing 2D plans. This higher efficiency is a primary benefit of signed and sealed 3D deliverables.

Q. Do you think signed and sealed 3D deliverables will become common practice? And if so, how soon might you imagine?

3D signed and sealed deliverables are becoming more commonplace in the industry. I would say within the next five years it will be typical to have 3D contractual deliverables throughout the industry. Three major transportation agencies already have projects that have been constructed with signed and sealed 3D deliverables, and there are many lessons learned from these early projects. AASHTO has also been very active in exploring this work through the Joint Technical Committee on Electronic Engineering Standards.

The industry continues to take critical steps toward widespread adoption. For example, in October 2019 at the AASHTO Fall Meeting in St. Louis, the state DOTs executive leadership formally adopted a new national standardised open data schema for sharing 3D data. This important action is a critical milestone in allowing BIM data to be shared seamlessly throughout the project life cycle, from design to fabrication, construction and asset management, regardless of the software used.

Q. What advice do you have for agencies or owners exploring this technology for transportation projects?

BIM for Infrastructure is taking hold in the U.S., and it will be a major paradigm shift for the transportation industry. Many transportation agencies are actively moving toward digital 3D deliverables, including Pennsylvania DOT’s Digital Delivery 2025 initiative. The industry just needs to be aware, the time is now to get proactively involved with this technology change.

Most agencies that have completed projects with 3D contractual deliverables have started with smaller pilot projects, ideally working with consultants and contractors with proven experience in 3D deliverables and automated machine guidance construction. There are many valuable lessons that have been learned on these early pilots, including the need to clearly identify the BIM level of development for the 3D deliverables, level of accuracy, intended uses and limitations of the data. Several agencies have also established a partnering committee with consultants, contractors and other stakeholders as they’ve moved toward 3D signed and sealed deliverables to get input on overall approach, process and deliverables.

The technology and change is coming fast, which is precisely why you shouldn't rush into it. As soon as you poke your head into this world, there are a million different directions to go, and understanding which of those are actually valuable can be difficult. That’s the importance of working with trusted partners and consultants who have the background to navigate the technology and determine how to get the best value out of it.

Each Experts Talk interview illuminates a different aspect of transportation infrastructure planning, design and delivery. Check back regularly to read more from the specialised experts and thought leaders behind our award-winning, full service consulting practice.