Experts Talk: Electric Fleet Charging Infrastructure Design with Sean Everett

Experts Talk is an interview series with technical leaders from across our transportation program.

How to Design Better Charging Infrastructure by Coordinating with Utilities and Managing Electric Demand

Converting a fleet to electric vehicles entails more than just buying new buses or trucks. Major infrastructure and operational changes are also necessary, and how these upgrades are designed and then implemented, perhaps in phases, will make a large difference in the performance of the resulting system. Setting up charging technology correctly from the very start can help get the most out of an electric fleet — and save money on demand charges.

Sean Everett, P.E., has managed a variety of projects that involved electric vehicle conversion, including a project to help Kitsap Transit in Washington begin to convert to electric buses. His experience with a variety of electrification projects enables Everett to identify and recognise the best methods to guide in a smooth transition to electric.

Electric Fleet Charging Infrastructure Design

Q. What factors should fleet owners consider when going electric?

A. There are several things fleet owners should consider. One key item is that large electric vehicles such as medium and heavy duty trucks and buses are still developing and improving. For example, at this time one electric vehicle might not be able to replace an internal combustion vehicle because of limitations in range and operation, charging speed and battery size. One approach to consider includes deploying electric vehicles on the shorter routes during the initial deployment stage or operate multiple EVs to replace a single diesel vehicle. En-route or opportunity charging such as layover points at bus transit centers or truck delivery locations may increase the amount of route-time that a single vehicle can operate.

Another key factor is managing electrical demand from the utility. As the technology continues to improve, the range will surely increase as the charging times will decrease. Our Zero+ Fleet Optimization tool takes a host of data such as route length and profile, GIS coordinates, and weather to assist in making data-driven decisions regarding optimal charging and bus routes.

When considering staged deployments at a facility, remember that electricity is now your fuel source so interruptions due to facility improvements to add more charging stations will impact and may decrease the ability to operate the fleet. Installing additional infrastructure or ductbank conduits during the initial stage will allow for smoother future improvements. Vehicle parking at charging stations requires a bit more room than parking for combustion engine vehicles. Planning for the facility improvements and their impact to operation early on will mitigate costly revisions or operational changes.

Finally, redundant power supplies may be needed to maintain operation during an outage. Several solutions are available to provide backup power, each with their own pros and cons. A second utility source can be very costly or may not meet every redundancy scenario. Battery storage is effective at reducing energy demand, but large fleets require large battery systems that are costly if they are expected to charge an entire EV fleet during an extended outage. Wind and solar power provide inexpensive power, but not generally in large enough quantities to supply power for large fleets. Backup generation is reliable but utilises the same hydrocarbon fuel source that the EVs were purchased to replace. Every site and every fleet are different so customised planning can help to understand and address these challenges.

Q. What are key design and operational strategies when adding new charging infrastructure to support an electric fleet?

A. It is important to manage the overall electrical demand, which can lead to monthly operational savings. Electrical demand charges are fees, beyond energy usage, levied on commercial and industrial customers based upon the highest amount of power drawn during a typical 15-minute billing period interval. This fee impacts customers who have large electricity loads over a short time. Depending on the utility rate structure, the demand charge may vary seasonably, or even within the course of a day, with the highest fee typically during the most active parts of each day.

So while electrical rates alone might make electric vehicles more economically attractive than fuel for internal combustion vehicles, the demand charges can make these vehicles more expensive to operate. By planning and designing the charging schedules to reduce the number of vehicles charging simultaneously, while still completing the charging necessary for daily use, these demand charges can be greatly reduced.

A large electric fleet charging all vehicles simultaneously could require the electrical load from an entire utility substation, which can have very high infrastructure construction costs as well as monthly operating costs that are then passed from the utility to the fleet. By properly planning and designing the fleet operations to reduce the peak electrical utilisation, the facility can accurately convey to the utility what the expected peak usage will be, both in the initial and full build out stages. The infrastructure improvements can then be implemented in stages, making the upgrades much more cost-effective.

The lower the peak electrical consumption, and the longer the duration, the less electrical demand costs will be. One way to achieve this is through smart charging, where multiple buses or trucks are connected to a single charger, for example overnight. A software system designates vehicles to be charged in sequence rather than at the same time so that it can reduce costs but also accommodate vehicle schedules. This system can be designed in a way that best meets fleet operational needs such as first-in-first-out.

HDR has also developed demand/load profiles for battery energy storage systems and how they can mitigate electrical demand for fleet operators. In most cases, these systems are currently cost-prohibitive, and it’s more cost-efficient to manage the demand through effective smart charging. As battery technology continues to improve and costs are reduced, these systems might be more financially feasible in the future.

Q. What are the different types of electric vehicle chargers available for fleets?

A. Because larger vehicles need larger batteries, haul more payload and generally have more rigorous usage, these vehicles require larger chargers as well. Direct Current Fast Chargers offer speed and flexibility, which allow for more efficient management of electrical demand while still meeting fleets’ operational needs.

There are three ways the vehicle can connect to a charger:

Plug in: Uses a cord and a plug, similar to traditional hydrocarbon fuel dispensers. These are typically used for overnight depot charging. More parking space is needed than conventional combustion engine vehicles.

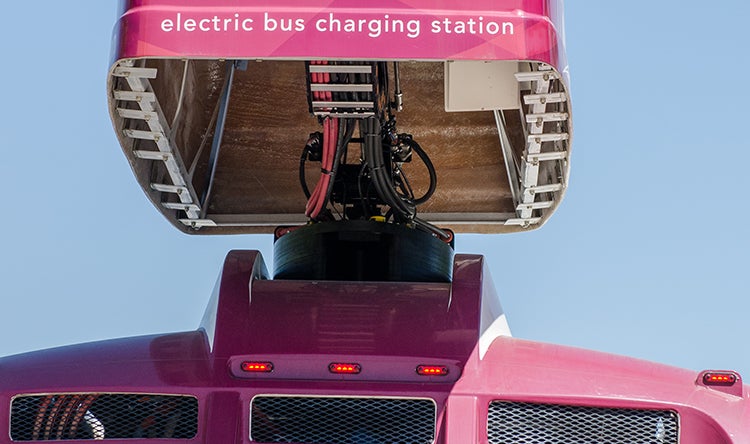

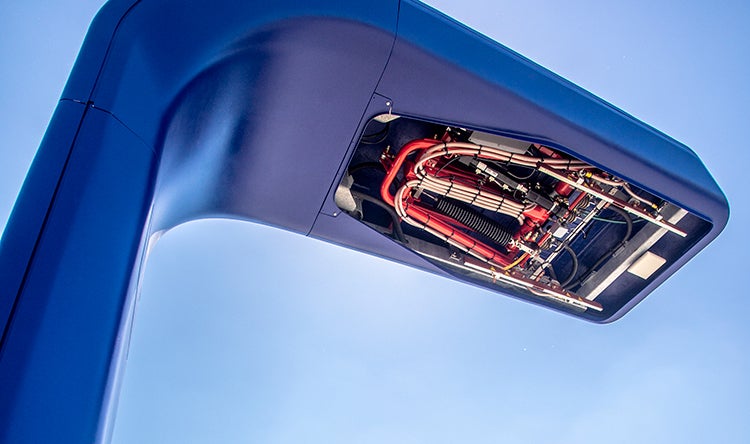

Overhead gantry: Connects to the top of the vehicle, also known as pantograph. These are used for en-route quick charging and are generally higher power than the plug in chargers.

Induction: These underground chargers work similarly to a wireless phone charger. Induction chargers are still under development with only smaller chargers currently on the market (with larger ones being tested). There is a substantial potential for these chargers, particularly in “opportunity charging” or en-route charging applications. In the future, they could also be embedded in the road and used to charge a vehicle while it is moving. This will likely become a more popular option for en-route charging as the technology progresses.

DCFCs vary in size, typically from 50 kW up to 500 kW. Larger chargers mean less charging time; however, some vehicle batteries may not be able to charge at the higher speeds and loads, so the vehicle battery communicates with the charger to regulate the charger loading within tolerable limits. Several companies are currently in the process of developing larger chargers (1 MW or greater) that will decrease current charge times for even larger batteries and larger vehicles.

Many fleets can be configured to charge two or three vehicles using a single charger. This charging configuration allows for lower infrastructure and electrical demand costs by decreasing the number of chargers. Proper planning is again key to making sure that the number of chargers are adequate to complete the necessary charging for daily operations.

Q. What role do utility companies play in the infrastructure for a fleet conversion to electric vehicles?

Starting the conversation with utilities early and communicating often is crucial to manage electrical demand and provide a successful electric vehicle fleet deployment. Many utilities have staff dedicated to vehicle electrification that can help provide fleets with information regarding rebate programs and other incentives for electrification. Most fleet electrification projects require some type of utility infrastructure upgrades, which may be as simple as a new service transformer or as large as a new distribution feeder and/or substation improvement. These utility improvements require time to plan, design and construct, typically anywhere from several months for a small project to many years, so providing well thought out planning for the fleet and the utility is essential.

Many utilities have also begun to develop rates targeted to electric vehicles and fleets. Communication with the utility will help the fleet owner to make informed decisions on how to receive service from the utility. We have also found that some electric vehicle rates don’t actually save the fleet operator money, and it might be more beneficial to pay the commercial consumer rate. On-site solar generation or the use of battery energy storage systems may also complement the electric system and help reduce the levelised costs for the overall project.

Q. How can fleet owners work with utilities to improve their rates?

Some utilities offer electric vehicle rates, which are sometimes but not always more beneficial to fleets than the utility’s large commercial rate.

Some large electric customers can improve the electric rates with the utility by entering into a contract with the utility to provide power at a reduced rate as many utilities and municipalities also want to foster electric vehicle use. However, reduced rates and other incentives often come with the stipulation that the utility will closely monitor the usage and how the electric vehicles impact the grid so they can apply the lessons learned to future electric vehicle customers.

Finally, the fleet owner may consider being provided power with a primary meter, rather than a secondary meter. While primary meter rates are lower, the fleet owner has more responsibility to operate and maintain the higher voltage and may need to hire additional staff, provide advanced training or pay higher maintenance costs.

Inspiration & Advice: Sean Everett

Q. How did you become interested in fleet electrification?

A. I kind of fell into it. Several years ago, we were working with a local university to plan their electrical infrastructure improvements on campus. The university had also received a grant to purchase two buses and a charger and asked if we could help design the electrical system improvements for the bus charger. For that project we treated the charger as just a large load and thought the large electric vehicles were more of a novelty. But as the technology has improved, electric vehicles are very much here to stay and will continue to be ever more prevalent.

Q. What advice do you have for someone just starting to work in the electrification field?

A. Vehicle electrification is a paradigm shift over current internal combustion fleets, and it’s bigger than just getting vehicles and chargers. Take the time to plan accordingly as jumping in too quickly can lead to delays, frustration, and redesign. Define what you want to accomplish, understand what is pushing the conversion, and then be realistic as to how long it will take. Finally, begin the discussions with the utility early so they can start to plan as well.

Each Experts Talk interview illuminates a different aspect of transportation infrastructure planning, design and delivery. Check back regularly to gain insights from specialised experts and thought leaders behind our award-winning, full service consulting practice.