When You Find Yourself in the One Water Nexus

One Water Issues: The Nexus of Drinking Water Supply Management, Lead and Copper Rule Compliance, and Recycled Water

Water utilities throughout the world are facing ever-more difficult challenges as they address declining water supplies, increasing demands from growing service populations and the need to improve the quality of water delivered to customers. In the past, each of these challenges was considered individually, with supply challenges addressed by looking for new water sources, water demands met by a combination of new supplies and conservation, and water quality goals achieved by implementing additional treatment processes. However, these challenges have become so complex that changing one parameter in a utility’s planning may create a ripple effect throughout the organisation and cause significant unintended consequences, if not proactively reviewed and addressed.

The City of Cheyenne, Wyoming’s Board of Public Utilities provides an excellent case study of one utility navigating these challenges. BOPU draws surface water from the Colorado River and Missouri River basins and groundwater from the High Plains/Ogallala aquifer — three of the United States’ most sensitive water supplies with regards to availability. In the years prior to the 1991 Lead and Copper Rule, BOPU primarily used surface water, with groundwater used on an intermittent, as-needed basis. Premise plumbing sampling results from this time found that water quality exceeded the 15 µg/L 90th percentile lead action level. In response, BOPU began constant, controlled surface/groundwater blending to stabilise distribution system pH and alkalinity as its Optimal Corrosion Control Technique. This strategy, along with other operational changes, resulted in a significant reduction in observed lead concentrations in system samples. Consequently, the utility achieved full LCR compliance for more than two decades. The latest results found sampled lead concentrations of 3.3 µg/L at the 90th percentile: only 22 percent of the action level.

Managing Drinking Water Supply While Maintaining LCR Compliance

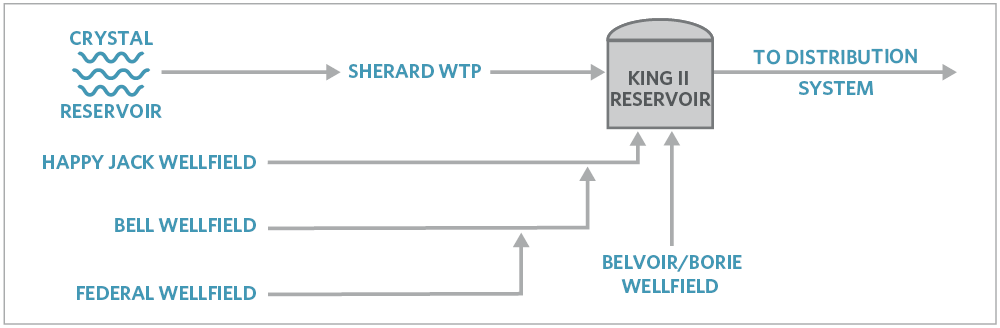

The source water blend is currently 70 percent surface water and 30 percent groundwater. However, groundwater availability is declining so BOPU must begin using more surface water to offset declining supplies and meet future demands. They also are making plans to recover aquifer storage in case of curtailment on the Colorado River System. Because the surface/groundwater blend was established for LCR purposes, blending changes must be carefully considered to avoid increasing lead concentrations, especially since the BOPU service area contains homes constructed when lead and galvanised iron service lines were common. We were hired to identify the required water pH and alkalinity entering the distribution system, to quantify the water quality changes of various surface/groundwater blends and to determine operational impacts to BOPU’s Sherard Water Treatment Plant (the facility treating the surface water).

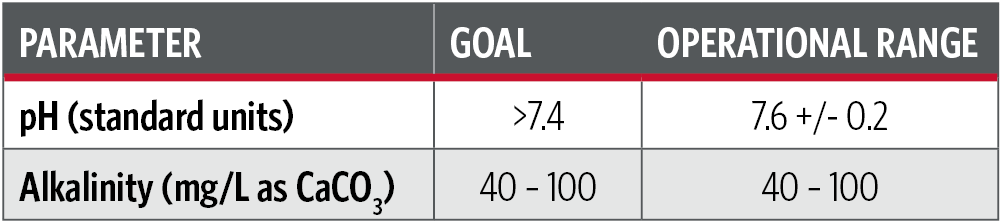

A comprehensive review of BOPU’s historical water quality was conducted, including characterisation at the King II Reservoir (where treated Sherard water blends with groundwater), the distribution system point of entry and throughout the distribution system. This review included using GIS to illustrate how pH and alkalinity change as finished water travels throughout the distribution system. The analysis determined that the operational water quality presented in the following table would be sufficient to maintain their OCCT.

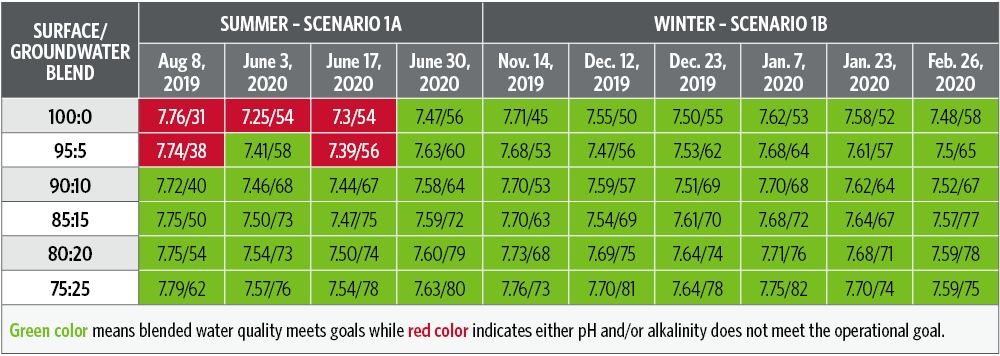

HDR and BOPU then conducted several rounds of bench-scale blending to surface and groundwaters at the Sherard WTP to determine the resultant pH and alkalinity. This testing was required because standard drinking water quality models were not accurately predicting the final pH/alkalinity values. The discrepancy was due to the plant’s very high elevation (6,500 above sea level), as lower partial air pressure affects the behaviour of dissolved carbon dioxide in water. Testing consisted of four scenarios:

- Scenario 1A – Worst-case groundwater quality blended with surface water quality in the summer season

- Scenario 1B – Worst-case groundwater quality blended with surface water quality in the winter season

- Scenario 2A – Typical groundwater quality blended with surface water quality in the summer season

- Scenario 2B – Typical groundwater quality blended with surface water quality in the winter season

Scenarios 1A and 1B represent the worst-case water quality conditions that BOPU could see in the water system. For this analysis, “worst-case” is defined as the lowest 10th percentile occurrence for pH combined with the 90th percentile occurrence for alkalinity. Scenarios 2A and 2B represent the typical water quality conditions that BOPU could see in the water system, with “typical” defined as the pH and alkalinities at the median occurrence. The table below shows the results of the worst-case scenario analyses.

The blending analysis also reviewed hardness, chloride-to-sulfate mass ratio, iron, manganese and several other parameters. The analysis found that blending up to 90:10 of surface water: groundwater could be accomplished without adversely affecting current corrosion rates. Higher surface water usage would require additional soda ash use to increase the alkalinity and/or pH of the blended water. While Sherard WTP’s use of soda ash would reduce corrosion and maintain LCR compliance, it also had the potential to negatively impact BOPU’s ability to use recycled water. We needed to assess the implications of solving this One Water supply problem (decreasing groundwater) upon the resulting water quality and availability of another supply (recycled water).

Adding Recycled Water to the Equation

BOPU operates a non-potable water system that supplies recycled water throughout the city for irrigation and reuse purposes. The recycled water consists of tertiary-treated Class A wastewater blended with drinking water to reduce salinity loading to irrigation customers. We used the blending study to assess the water’s Sodium Adsorption Ratio, a factor likely to be affected by the earlier changes. SAR is an irrigation water quality parameter used to manage sodium-affected soils and as an indicator of a water’s suitability for irrigation purposes. Fortunately, our analysis found that optimised soda ash application, combined with a change in disinfectants, would actually result in lower SAR values and improve the quality of the recycled water. BOPU could have both LCR compliant drinking water and a stable recycled water supply.

The One Water Solution

We were able to determine that BOPU could reduce its dependence on groundwater without compromising current corrosion control requirements or its recycled water supply. Thus, the change in BOPU’s future water supply portfolio can proceed and still allow the utility to have more reliable drinking and irrigation water supplies to meet future demands. In addition, the change allows BOPU to defer the expensive wellfield upgrades that would be required to maintain groundwater output and reallocate that investment to other infrastructure needs.

Authors:

Pierre Kwan, P.E., Northwest Water Treatment Lead, HDR, Seattle, WA

Clint Bassett, P.E., Cheyenne Board of Public Utilities Water Treatment Division Manager, Cheyenne, WY