Experts Talk: How to Get the Most Out of Freight Planning with Keith J. Bucklew

Experts Talk is an interview series with technical leaders from across our transportation program.

Getting the Right Goods to the Right People at the Right Time

Freight movement is our economy in motion. When done right, a freight plan can help our clients ensure that consumers get what they need. Freight plans not only support economic growth, but also integrate freight movements into communities in a way that improves overall quality of life.

Keith J. Bucklew is our freight planning practice leader and provides direction and guidance for freight planning projects. He has more than three decades of varied experience in both the public and the private sectors. Bucklew knows how to help clients go beyond the requirements and create a freight plan that truly benefits the entire community. In this interview, he explains the importance of freight planning, how to get the most out of it and how it relates to the supply chain issues of 2021 and 2022.

Q. Why is freight planning critical to the economic success of a community or region?

A. Freight movement can be best understood and visualized as the economy in motion. Moving goods and commodities from their point of origin or point of manufacture to the customer is necessary to consummate a transaction. Nothing happens until something moves. Freight mobility is all about getting the right product, to the right place, at the right time, to the right person, for the right price. All this activity requires people — workers who manufacture the products, transport the products, distribute the products, and ultimately people who purchase and utilize the products. Producing, moving, and distributing products creates employment — jobs. Buying products fulfills consumer needs and wants. Both aspects support quality of life by providing an income via employment and meeting personal and business demand for consumption. Without freight movement, economies become stagnant.

The Kentuckiana Regional Planning and Development Agency in Louisville is an agency that’s improved its economy through freight planning. Its freight plan identified and prioritized mobility and safety impediments. KIPDA identified these high priority projects and collaborated with city and county jurisdictions to get the projects included in the respective transportation improvement plans. This expedited the development of important projects and lifted the area’s economy.

Q. How can a client get the most out of freight planning?

A. Freight plans are customized to fit the needs of each client. No two are alike. Freight plans generally focus on these topics:

- Mobility (efficient and reliable movement)

- Economic development

- Infrastructure: maintaining existing assets and developing new capacity

- Safety

- Environmental protection

- Equity and community

The U.S. federal government requires state departments of transportation and metropolitan planning organizations to develop freight plans, and if done right, those plans can have great benefit for a community or state. A well thought out freight plan supports economic development, addresses private sector demands, matches funding and financing options for projects, and provides justification and transparency for investment decisions.

A freight plan is a blueprint for action that identifies the implementation steps that will solve freight needs and issues. In order to create an actionable plan, a client must first determine how the plan will be implemented when it’s finished. Then, working backwards, the plan will include the pieces needed to become a reality.

For example, in 2020-2021, the HDR team developed the Texas-Mexico Border Transportation Master Plan to identify and solve cross border and regional needs and issues for freight and people. The plan included 29 crossing locations with various issues and complexities. We knew going in that we wanted to make crossing activities more mobile, fluid and safe, without jeopardizing security. So, as we created the plan, we focused on identifying issues and needs while developing solutions to improve efficiency, reliability, and safety. Standardizing policies and procedures, incorporating technology, and prioritizing projects provided the best approach to develop a plan that could be implemented. This multimodal freight plan solved mobility issues on both sides of the border and received unanimous support from a wide range of participants from Mexico and Texas. It is now guiding development of projects, programs, and policies to improve freight mobility to support the economic development of Mexico and the United States.

Q. How does freight planning fit into the larger transportation picture?

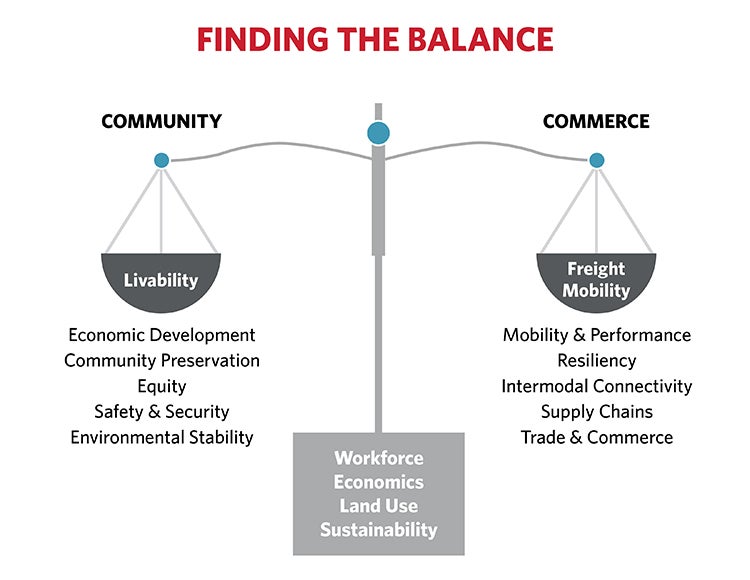

A. Freight mobility solutions must consider community needs and livability. State DOTs and MPOs develop Long Range Transportation Plans, or LRTPS, the overarching transportation plan which guides all other planning. It is critical that freight plans support and align with LRTPs by conducting a thorough analysis of freight movement activities and freight needs for manufacturers, industries, businesses, and issues for all five freight transportation modes: trucking, railroads, maritime, air cargo and pipeline. Each state and region is different, so finding the right balance between freight needs and community needs is necessary to alleviate friction points or conflicts brought about by having to share infrastructure and physical space.

In some cases, an area is very freight-centric and less concerned about livability. In others, like a metro area, it’s very much community and livability focused — yet you can still have a huge amount of freight moving through the vicinity.

To determine the community’s needs, we use a variety of data sets, including congestion and safety crash locations, land use, disadvantaged population areas, transportation equity and more. Then we conduct stakeholder and public engagement to complete the picture.

Once we have an understanding of the needs of the community, we use that to prioritize recommendations to find win-win solutions. For example, a designated truck route network can allow for better flow of freight and more safety for the cars, bicycles and pedestrians on other streets. Another example is curbside management techniques such as common unloading zones with short dwell times and off-hour deliveries.

Freight movement is necessary to support livability needs; while there may be friction points between the freight and livability, in general, one can’t really exist without the other.

Q. How is technology impacting freight transportation?

A. State DOTs and MPOs are challenged by the plethora of technologies being developed and adopted for use. These agencies need to understand their roles and responsibilities in supporting freight carriers adoption and usage of technologies.

One technology that gets a lot of attention is autonomous operations. Long stretches of roadway driving may be acceptable soon for autonomous trucking operations. However, urban environments are complex and pose higher risks for safety and mobility, and the initial costs associated with autonomous technology is high. Adoption of autonomous vehicles will be a gradual process but over time, there is excellent potential to improve efficiency, safety and transportation costs.

To further compound the “technology acceptance” conundrum, legislative action may be required as states may not view these matters the same. Hence, carriers are likely to be confronted with a patchwork of regulations and laws that render interstate travel challenging. For example, one state may allow trucks with autonomous operation technology to operate without a driver in the cab, while another state may require a driver to be in the driver’s seat. A truck that is crossing a state line can’t simply change its technology — or add a driver — based on the regulations. So different regulations make it more difficult for companies to adopt any technology at all. If or when the federal government standardizes regulations, that would create certainty in the trucking industry and these technologies are likely to take off. In the meantime, states can work with neighbouring states to create uniform guidance for trucking firms, which helps promote the use of these technologies.

Other technologies that are gaining popularity and are worth considering as a client develops a freight plan:

- Optimization models to select routes for trucks that can minimize the number of miles driven, select when and where to refuel, monitor driver operational habits, monitor hours of work, and provide real-time roadway conditions

- A transition from fossil-based fuels to more environmentally friendly fuels such as natural gas (compressed and liquified) and electric.

- Safety features and improvements such as lane departure warning, better visibility, automatic braking, etc.

- Advancements in aerodynamics that reduce fuel consumption, trailer tracking systems that enhance cargo security and truck platooning technology

- Similar technological and operational advancements in railroads, air cargo carriers, maritime vessels, and even pipeline operators

Q. How does freight transportation planning support industrial supply chains?

A. In 2021 supply chain disruptions were elevated to the global spotlight.

First, it’s helpful to understand what a supply chain is: It is the journey by which a good gets from its point of origin to the hands of the consumer. It consists of nodes, which are points where the product either gets enhanced or transformed, or it changes transportation mode.

Supply chains vary by industry and business, and they are optimized to maximize customer service and minimize cost. Within a particular industry, there are similarities, but even they vary by individual crop, manufacturer, and even geography. Supply chains are dynamic, frequently being altered to adjust to carrier availability, variable costs, customer demands, trade sanctions and a host of other factors that disrupt the flow of goods and commodities.

Many of the supply chain issues that have made the news are a result of labour shortages at some point in the process. For example, there might not be enough truck drivers to transport the goods from the warehouse to the store. Or maybe there aren’t enough workers to offload items at a port or airport. This creates backlogs and the product does not make it to the consumer as quickly as it typically would. Other causes include port congestion, shipping container shortage, container chassis shortage, pandemic related restrictions, commodity supply lagging behind demand, and logistics cost increases.

Short-term freight planning can help agencies understand where these pinch points are in a chain, allowing the development of solutions. For example, in 2021 HDR assisted the Georgia Port Authority relieve these issues by developing a Supply Chain Relief Program, which was accepted by the Biden-Harris Administration’s Supply Chain Disruption Task Force and was immediately funded for implementation.

We determined that a container backlog at the ports was occurring because the warehouses and distribution centers had labour shortages that restricted their ability to accept inbound loaded containers from the port. Our plan identified five inland locations for temporary storage of those goods, including unused space at an airport and rail locations. This allowed the backlog at the port to clear and other goods to move as normal.

Inspiration & Advice

Q. How did you become involved in freight planning?

A. I took a circuitous route to my job now. I started as an Army officer out of college. There I realized that you can’t be effective without logistics. When I left the military I went to a national trucking firm. Then from there I went to be a corporate supply chain manager. Then from there I went to a state DOT as the freight mobility director.

Eventually I went into consulting, and here I am. I worked in the private sector, I worked with the government, now I’m consulting. My varied experience helps me understand all the perspectives of stakeholders when creating a freight plan.

Q. What advice do you have for someone just starting their career in freight planning?

A. Successful freight planners have very diverse backgrounds — urban planning, supply chain management, engineering, economics, etc. Very few academic programs focus solely on freight planning and successful freight planners need to have a working knowledge of many different topics. If you are interested in becoming a freight planner, take some “field trips” to visit trucking firms, rail carriers, air cargo facilities, intermodal facilities, locks and dams, distribution centres, and manufacturing facilities. You can also join a local supply chain group like the Council of Supply Chain Management Professionals. The movement of freight is led by the private sector and they can be a great resource in educating you about what they do and their needs and issues.

Each Experts Talk interview illuminates a different aspect of transportation infrastructure planning, design and delivery. Check back regularly to discover new insights from the specialized experts and thought leaders behind our award-winning, full service consulting practice.