Experts Talk: BIM and 3D Design in the Field with Alexa Mitchell

Experts Talk is an interview series with technical leaders from across our transportation program. Photos taken prior to the COVID-19 pandemic.

Transition from Plan Sheets to Models Holds Great Potential but Requires Strategic Thinking by Transportation Owners

Building information modelling and 3D design is fundamentally changing the way that transportation projects are delivered. Models are replacing plan sheets and some states are even exploring their use as the new legal documents used for design and construction. This creates new opportunities for accuracy and collaboration. At the same time, this shift away from plan sheets is disrupting processes that field staff use today.

Alexa Mitchell, our highways and roads BIM director, has a background in national-level research and regional implementation, helping transportation leaders across the United States to deliver projects more effectively through BIM technology. In this interview, she discusses the benefits of 3D models, explains what agencies need to know as they increase their use of BIM and addresses the challenges field staff face when adapting to 3D models.

Q. How do new 3D deliverables affect the way field staff such as contractors and construction inspectors operate?

A. This is a primary concern for many people. They are used to relying on plan sheets for information about what they’re constructing. If those sheets are no longer provided, how will they know correct measurements, dimensions, quantities and more? As I speak to field staff and others across the country my answer is similar — your job is not changing; you still must do the same things you used to do. But the tools you use are changing, and those new tools can provide additional information and benefits not previously available.

New skills will be needed to use these tools to access information that is being presented in a different medium. Specifically, instead of printed sheets, you can expect to access the designs via a tablet or computer. Usually in the field it will be a mobile device of some sort, with an app used to extract needed information from 2D and 3D models. That information could include locations and elevations, notes, dimensions and pay item quantities. Because these models are tied to GPS locations, GIS mobile apps can also be used to create customised perspectives, allowing workers to see plans from their own location on the project site when desired.

With many people of differing technological familiarity using 3D model viewers, intuitiveness and ease of use are key considerations. As contractors and agencies explore the programs available, they should consider the functions they will need and the requirements of each role that will use it.

It’s also important to note that many apps and views of models within apps are customisable. If there is a particular view that would make work easier — for example, recreating a similar look to familiar flat sheets — expressing a preference to designers ahead of time can help make that happen.

Q. What do these new models and apps look like for those in the field?

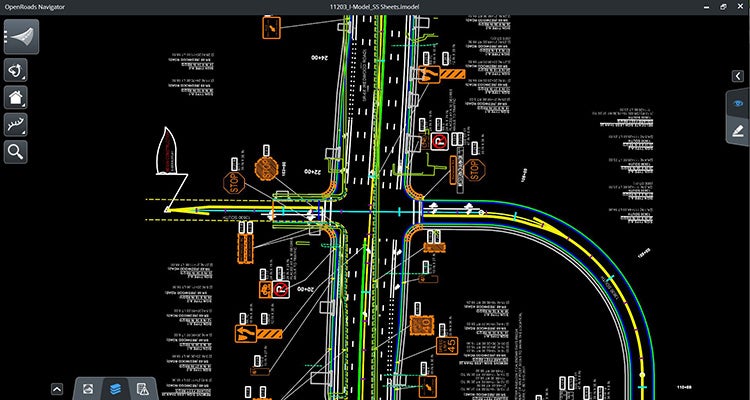

A. Instead of traditional plan sheets and cross sections, you’ll start receiving digital plans as a combination of 2D and 3D information:

The information will be similar to what has traditionally been displayed on plan sheets, with line work as well as notes, callouts and stationing. But you’ll be able to zoom in and out and navigate the entire project using this view. You’ll also be able to turn layers on and off to focus on specific aspects of the project or declutter the view. One easy way to think about it is to imagine these 2D digital deliverables as a long giant PDF roll-plot, but instead of paper you view it with a tablet and a viewer app.

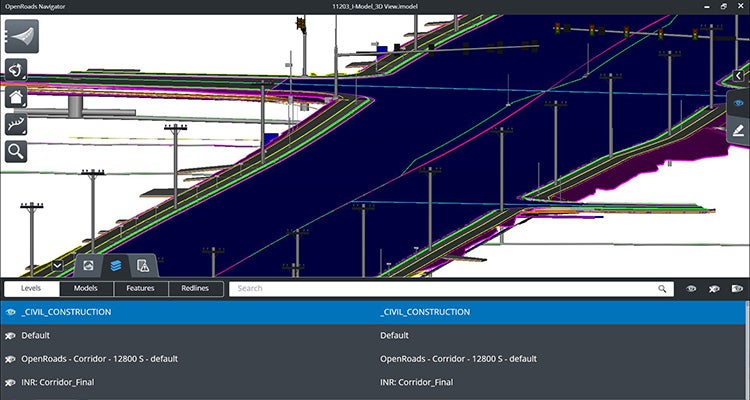

A key difference and benefit is that it will also now be possible to view the design in a 3D environment. These 3D models will contain the information commonly found in plan, profile and cross section sheets. Examples include stations, elevations, dimensions and parameters, and pay item information. The 3D model elements can also have files attached, such as PDFs of the corresponding standard drawings, spreadsheets with calculations, etc.

Q. What's the benefit of 3D models to owners and those in the field?

A. 3D images communicate design intent much better than 2D representation that requires multiple pages to show an entire project. A 3D perspective offers information that you may miss in 2D. Even those with lots of experience still miss things when piecing together different sheets like a puzzle. Beyond that visualisation aspect, there are clear benefits to different members of the project team:

— Owners of the assets get a database of information faster and at less expense — and sometimes this is information they wouldn’t have otherwise. For example, several years ago, there was a problem across the United States with a specific guardrail end terminal. People needed to know where those terminals were located. But in most cases, nobody knew exactly which guardrails they had. So owners sent people to drive up and down their roadways, trying to figure out where these devices were located. If they had databases with the exact locations of those assets, that would have cut out days or weeks of field verification.

A 3D version of assets, including what they look like in their location, can serve as the container that houses detailed information like the manufacturer, installation date and any repairs — all information needed to upgrade infrastructure. Our team provided this kind of as-built database on the recent Gov. Mario M. Cuomo Bridge project, giving the owner on delivery a virtual model that included information on each part and its status.

— Contractors also benefit from being able to see a more complete picture and virtually seeing the project before it is built. This can save considerable time. Contractors can use the 3D deliverables to pose questions and get information from people more quickly. With everybody looking at the same model, there's less confusion. Overall, we're observing that they save time in the field and that makes accelerated timelines more feasible.

Contractors can also use 3D models, depending on the level of detail, for safety reviews. And they can use a model for understanding what materials they need to be ordering. Contractors can connect these models to their schedule and the materials needed at certain milestones, to virtually see a sequence of events. So for the contractor, it's great for estimating purposes.

— For construction inspectors, a 3D model can mean easier documentation of what they see in the field. While undertaking their inspection, they can use the virtual environment to pinpoint the as-built asset they are verifying and compare it to the model. Then they can export that information as validated to a separate database, freeing them from manually re-entering information about their observations. Rather than filling in forms and creating sketches, they can use the model’s virtual environment to streamline their documentation.

Q. How does a transition to 3D deliverables and the needs of those in the field affect designers and others earlier in the project process?

A. Part of the challenge right now is that there is no standardisation of what needs to be put into a model. That puts the onus on designers to develop models that fit what those in the field need.

We've been working with the Utah Department of Transportation, for example, on some of their 3D modelling pilot programs. One of the major areas of feedback from contractors on those pilots was a lack of consistency in the models. Contractors knew that all the information would be in the model, but where that information was, how it was presented, how it needed to be accessed, was different depending on the designer.

Partly as a result of feedback like this, UDOT hired HDR to help them create the nation’s first model development standards manual. It lays out specifics on what needs to be included and what should be left out of a design. For example, do designers need to model topsoil or not? There isn’t a wrong answer, as long as the contractor knows consistently one way or the other. If it’s left out of the calculation, contractors will need to know that and account for it in their estimates and construction plans.

Developing those standards during model development will be key to improving accessibility and ease of use for those in the field that use the model. If they can count on it looking the same every time, with a consistent method for finding the information they need, it will be much easier to adapt to a new process.

Q. What needs of field staff should be considered as agencies transition to 3D models instead of plan sheets?

A. It’s not just buying software. You must think about all of the components. The technology can easily become the focus in discussions about the transition, but it is often the other parts that are more difficult.

When you know you want to deploy BIM, you need to know the entire scope of what will be required. That begins by developing a plan that addresses your specific needs, looking at not only the technological tools but also the human component. How are you going to bring people along who have been doing things the same way for 20 years? How do you transition DBEs and smaller firms? What does the stakeholder communication plan look like? All of that is part of a wider strategy that needs to be developed.

HDR is helping the Pennsylvania Department of Transportation with this transition using a “crawl, walk, run” approach to fully adopt digital delivery by 2025. Our approach is to take on activities that have lower barrier to entry to achieve small but rapid success, setting us up for more complex tasks.

Some of the change will come from specific new guidelines tailored to each role. A designer might be told: You haven’t included this before, but you need to include A, B and C from now on for those on the construction site. Here are the tools you need to use. Here’s a checklist to use. This is the training you must take. This is how you collaborate with people.

On a wider scale, change involves shifting thinking away from plan-centric work to data-centric work, where information can be accessed and used in multiple ways. Instead of drawing 2D lines on a piece of paper, we need to design 3D objects that virtually represent the physical asset and all the information needed to construct and inspect the asset.

Pilot projects have proven extremely helpful for improving processes, especially for agencies that are exploring the possibility of making the 3D model the legal design document. HDR has assisted with many of these early 3D deliverable pilots in the U.S., and in many cases, adjusting to a new process can be more difficult than simply learning a new tool. If the tool is intuitive and is the right tool, it could just take a day or two of training before it can be used. But new processes and navigating a new medium often take more getting used to for staff. Completing a pilot project and seeing the tools in action, along with learning from any mistakes made, are often necessary to help staff become comfortable.

Inspiration & Advice

Q. How did you become involved in BIM and 3D design?

A. It was about 15 years ago during my tenure with the Missouri DOT. I was asked to work with regional contractors on finding a solution for delivering 3D models they could use with their GPS-guided earthwork equipment. I’ve been working on advancing the practice ever since, and I have met incredibly smart people along the way that have taught me so much!

Q. What advice do you have for those just beginning to encounter 3D design in their career?

A. It’s an exciting time to get started. The tools are getting better, and we have learned so much. Definitely, look for ways to learn and collaborate with your peers, and don’t be afraid to try new ways of doing things.

Each Experts Talk interview illuminates a different aspect of transportation infrastructure planning, design and delivery. Check back regularly to gain insights from specialised experts and thought leaders behind our award-winning, full service consulting practice.