Experts Talk: Benchmarks for Success in Alternative Delivery Procurement with Doug Jackson

Experts Talk is an interview series with technical leaders from across our transportation program.

How Owners Can Prepare Complex Transportation Programs for Long-Term Success, Starting in Procurement

When starting a major project, infrastructure owners have a varied menu of delivery options in front of them. With multiple options, it’s tempting to default to the cheapest or quickest alternative. But long-term success is not built on bargain hunting. As transportation agencies consider the full life of their programs, it’s important to consider more than the initial award value, which all too often can vary considerably from the final tally.

Long-term planning and a big picture approach are nothing new to Doug Jackson. A principal program manager with more than 25 years of transportation industry experience, he has led major, complex infrastructure projects for rail, highways and transit, from concept development through design and construction and into operation. Currently he is serving as the principal program manager for the CA$10.9 billion Ontario Line transit project in Toronto. In this interview, he explains how to better measure the success of procurement, explains current challenges in alternative delivery and shares how improved risk management is changing the project delivery landscape.

Q. How do you measure success on a project and how does that change how you approach procurement?

A. Often, our industry measures early success by the award cost, which is not the same as actually completing a project successfully. There is also a lot of emphasis on “what's the fastest way to go,” not necessarily whether that arrives at the best outcome. Cost and schedule are both important, but setting up a complex project for success requires consideration in its entirety from beginning to end.

In past years, the tried and true delivery method used almost everywhere was design-bid-build. That method works well in many cases, particularly straightforward ones. But as owners embark on more complex mega-programs that can involve many interconnected projects, procurement requires new thinking, including an openness to delivery methods that can better handle the complexity without leading to delays and overruns.

When planning a procurement process, I’m asking: Will the project meet the goal of the client? Is it likely to finish on time and finish on budget? I want to ensure that we are weighing multiple factors, including cost, schedule, quality and risks. This is why choosing the right delivery method is so important. The focus needs to be on whether the delivery method is adequate to handle the project’s complexity and provide predictable outcomes.

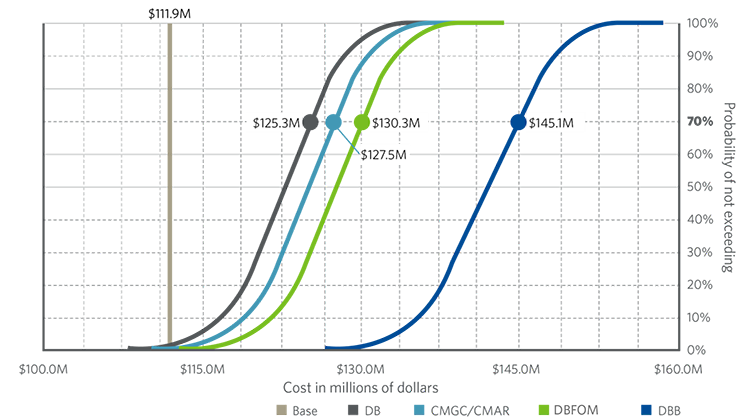

There can be a concern that some alternative delivery methods are more expensive. What we’ve seen with some of these delivery methods is much less cost growth over the course of the project. Progressive delivery models in particular have been able to reduce change orders and finish much closer to the initial award level. In other words, what may seem a higher cost at procurement turns out to be a much better investment by completion.

Q. How can owners improve their procurement strategy to better assess the right delivery methods and achieve these long-term goals?

A. Choosing the right delivery method starts with understanding the risks. We often work with owners on a customized evaluation of the delivery methods available. We begin by evaluating the complexity, the major risks and obstacles. We set four or five major goals for the project — minimizing the construction impact on the user, reducing construction access issues, etc. Then we compare delivery methods, using the individual requirements and risks.

We're doing this now for a client who has nine commuter rail projects and is asking if they should combine all nine into one major program or if it would be better to proceed with nine individual projects. To best answer this question, the analysis needs to extend to each individual segment. Within the nine segments, what is the right approach for each, which delivery method will best control and mitigate risks? Which delivery method is the best price not just at bid, but the final price at completion? Which delivery method provides optimal schedule? Is going faster better or is there a balance between speed and cost? Are sufficient resources available for the contracting community to construct the entire project at the same time or should the construction be staged? How do the effects of managing nine separate projects present risk to the entire program?

Getting the answers to these questions is part of making an informed decision and requires a small upfront investment of time. But the weeks or few months required to better understand procurement and delivery options can pay great dividends over the course of a multiyear project or program.

Q. How has risk transfer to contractors affected the success of some complex alternative delivery projects?

A. In recent years, speed has been a big selling point for alternative delivery. The process is no longer linear, so teams can overlap parts of the process and compress the overall timeline. But with that faster process comes risk, particularly in fixed price design-build. There’s likely less design complete and less quantification by the time of bidding. That in turn means more risk and more contingency is bid into the cost of the project. Many owners see this shifting of risk as a key benefit, allowing contractors to manage risks that they can handle. However, we see problems occurring when contractors are actually not able to handle this much risk and the magnitude is too great.

Third party risk is one of the most difficult areas to effectively quantify. Much of this stems from limited agreements and third party understanding of the impacts in advance of the bid. Questions that are not always answered include, how will the project affect the local municipalities where we're building these projects? How will it affect private utility companies? How will all of the environmental permitting be handled? More problems arise when third parties set their own timelines, often causing delays in reviews or other milestones.

These risks are pushed to the contractor, however the contractor can't accurately quantify third party risk, and therefore bid contingency is often inaccurate. This leads to contractors increasing the cost of their bids and speculating on the risk profile. Once they get into delivery, the risks begin to increase and managing them becomes very difficult. This has a double impact. Owners often feel like they paid for that risk transfer. But when the risk occurs, the owner still has to work with third parties to mitigate that risk.

Q. How is this struggle to accurately quantify risk changing procurement and bidding? How should owners respond?

A. We're seeing declining interest in fixed price contracting, including design-build or public-private partnerships. These very complicated projects are often boiled down to a set of performance criteria, and it leaves a lot of gaps. Contractors are asked to commit to a fixed price and date-certain delivery on very preliminary information. That's led to the contracting industry really pushing back and saying there’s too much risk, the outcomes of these projects aren't good. We need more predictable outcomes and projects that we can better control.

On the insurance side, we're seeing real difficulty in getting insurance, especially professional liability insurance. On the finance side there are large concerns, such as: How much risk are they being asked to bid? Can they quantify that risk? And even if they can quantify it, can they control the risks if they arise?

More often now, contractors are doing their own analysis of the risk profile and then translating it into contract terms. If contract terms and risks are too onerous, they won't even bid. They'll walk away. This is leading to fewer options for owners, potential delays or a rebid due to lack of competition.

Owners need to keep an eye on the market. If there are multiple projects to bid, contractors are going to pursue projects with less risks and avoid those with too much uncertainty. For contractors, an alternative delivery procurement can mean an investment of 12-18 months of their top staff’s time before construction even begins. If they see that there is no agreement with an affected municipality, a lot of public controversy, and political support is wavering, understandable hesitancy to commit staff will occur. Before a bid release, owners will want to ensure they are prepared and set up for success. This includes completing permits or agreements that need to be in place.

Any analysis of the delivery method should include the contracting market and its availability. Owners will attract the industry by understanding that their complex and risky projects are worthy of contractors’ investments to bid.

Q. How are newer progressive delivery models changing this situation?

A. The progressive models — construction manager/general contractor or construction manager at risk, progressive design build, integrated project delivery and alliance — are game changers for the industry. They are the only models that allow teams to visualize, mitigate and allocate risks before final costs are determined.

These models build on a highly collaborative, iterative process in step with the owner. The contractor and designer cooperate with the owners to determine the best solution for a particular location.

If you take a transit station project, for instance, the owner may have an idea of what they want for the station. The design and contractor team take that initial concept and fit it to a specific location, adjusting for the constraints and figure out how to make it work. The contractor can then price that concept, often with confirmation from an independent cost estimator. Doing more design before setting a price allows risks to be identified and mitigated prior to determining a final cost. This also means a better opportunity to determine the best party to own the risk contractually.

Multiple studies have validated the success of these methods, particularly in providing accurate bidding. While each project is unique, we generally see noticeably less cost growth over the life of a project when a progressive model is used. This is important to note, as some of these methods can generate more expensive bids. But the difference in cost is often wiped out or reversed as change orders and schedule delays increase the bottom line on a design-bid-build or fixed price design-build.

It’s clear that progressive models can be a great solution sometimes. Ultimately, the options in the toolbox for owners have increased. Most importantly, selecting the right delivery method is critical in getting projects done in a timely and cost-effective manner.

Inspiration & Advice

Q. How has your career led to a deep expertise in alternative delivery?

A. Early in my career, I got really focused on project management, which provided a portable skill set. Because I was good at project management, I was able to manage projects in multiple sectors including highways, freight, transit and more. And with some luck in good timing, I started my career with HDR more than 20 years ago when alternative delivery and design-build were just taking off in the U.S. I’m very appreciative of the multiple opportunities involving nearly all delivery methods with public owners, across North America.

Q. What advice do you have for somebody interested in following your career path?

A. Be open to change. Be flexible and agile. Many engineers thrive in an environment of following the tried and true. That’s fine, and in many cases it’s very important to follow the prescribed roadmap. However, project management within alternative delivery is different. We draw the roadmap and we blaze the trail. That takes confidence. Some things are going to work and some will not. Adjusting on the fly to constantly improve is an art that takes an entire career to master.

Each Experts Talk interview illuminates a different aspect of transportation infrastructure planning, design and delivery. Check back regularly to discover new insights from the specialized experts and thought leaders behind our award-winning, full service consulting practice.