Switching to 3D BIM Deliverables: 6 Factors Transportation Agencies Should Consider

Considerations for Moving from 2D Plan Sheets to 3D Models

By Daniel Prokop and Will Sharp

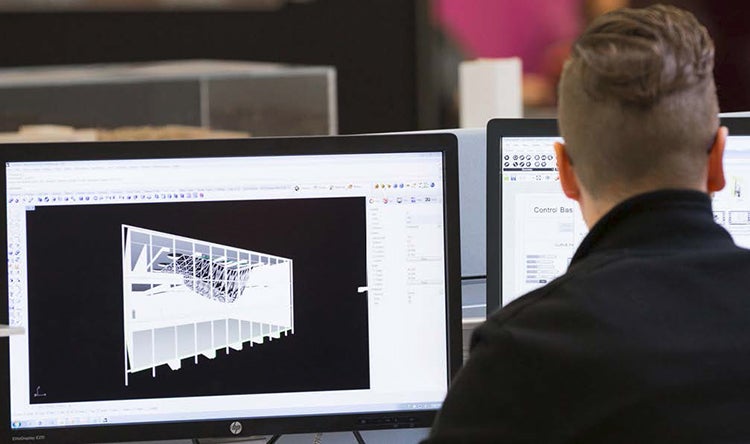

3D engineered models and BIM for Infrastructure have been used for years as an avenue to provide extra information and visualizations for road and bridge projects. Despite the fact that building information modeling has been used to supplement project development, 2D paper plans have remained the contractual deliverable for construction. That traditional method is starting to change.

As agencies and the industry become more familiar with BIM and its capabilities, some state transportation agencies are taking the next step, making the 3D BIM model the contractual deliverable for transportation projects, and in some cases eliminating the 2D paper plans. Pilot projects that include signed and sealed 3D deliverables are being completed by five major transportation agencies across the nation.

HDR has experience completing numerous signed and sealed 3D deliverables for roadway and bridge design in multiple states. We provided roadway and bridge design projects to DOTs in Utah and Iowa, and are assisting the Illinois Tollway in developing their approach to 3D deliverables. We are also supporting the Pennsylvania DOT in achieving their vision of moving to 3D digital delivery.

Like the transition from hand-drafting to CAD, this step signals a sea change in the industry. As adoption continues to grow, it brings with it the promise of added value in the form of improved constructability, higher quality, better interdisciplinary coordination and enhanced visualization. However, it’s not without challenges including standards that are still under development, varying levels of software adoption among parties, potential shifts in responsibility, and the basic need to develop methods for delivering signed and sealed 3D plans.

Following are some important factors for agencies to consider as they enter this new era:

Scope & Fee Standards

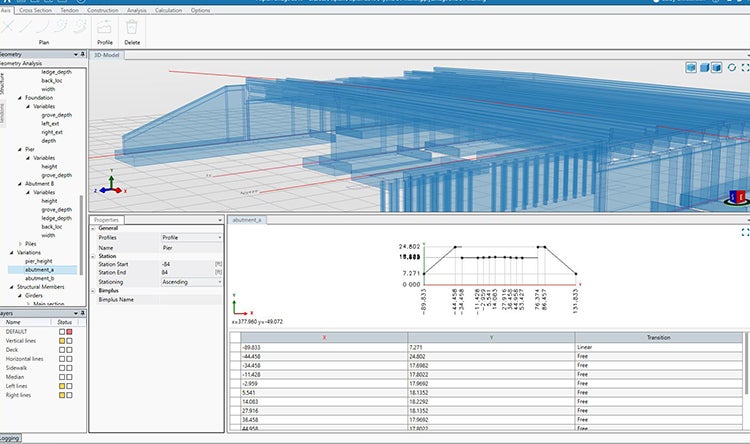

Though a number of agencies have completed pilot projects and are advertising additional projects for bid that require 3D deliverables, the scope and fee for such deliverables have yet to be standardized. Agencies considering inclusion of 3D requirements should take into consideration the intended use of the model and its needed accuracy. Key questions to ask to guide programming and design development include: Is it a design tool? Is it a visualization? Is it a contractual deliverable? Will it be used for future asset management? Does it need to fit all of the above?

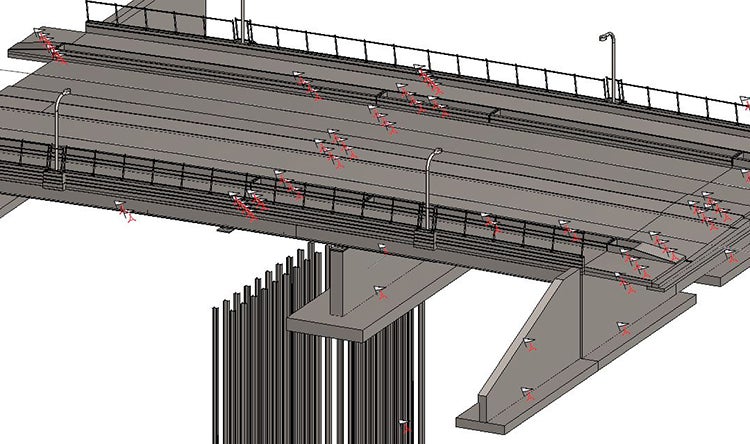

All parties should also be clear on the Level of Development required in models for all elements of the project. Should a 3D model simply identify that a wall exists? Show the approximate size and location of the wall? Or does it need to include full detail of the wall including its external and internal components?

Developing a well-defined and tailored expectation of the intended use, Level of Development and accuracy of all the elements to be modeled for delivery is foundational to overall success. This definition will lead to achieving a clear understanding of what agencies, designers, construction managers and contractors can expect of the model and how it can be used.

Some flexibility is also important. 3D deliverables remain a relatively new feature, and signed and sealed 3D models are extremely new to the transportation industry. Project needs and possibilities can change as software continues to improve, technology adoption levels increase and industry standards are written, particularly on multi-year projects. Consider a provisional/T&M/contingency fee contract to anticipate the need for modification and provide risk reduced methods for both agencies and designers to explore and determine the best practices, paving the way for a successful future in delivering transportation projects in 3D.

It is also important to recognize that the trend toward 3D deliverables is actually part of a larger movement, which is the trend away from traditional 2D plan sets and the adoption of full electronic delivery. Providing a 3D model as the deliverable makes up a substantial part of this change, but there are numerous parts of a project that do not make sense to provide in a 3D environment. Some examples include pavement markings and maintenance of traffic, drainage schedules, quantity tables and standard details. Many of the pilot projects that have been performed under the umbrella term “3D deliverables” have actually included 3D model files, 2D CAD files, Excel files, PDFs, xml files, various surface file types and a host of other database file types. In defining expectations of deliverables clearly, it is important to acknowledge this distinction.

Varying Levels of Adoption/Compatibility

Most contracts involve review by outside parties such as utility companies or affected municipalities/communities that are a stakeholder in the project limits. Any design must be consumable by these parties who will likely have varying levels of software adoption, compatibility and expertise. Any agency or designer implementing 3D and planless delivery on a project should anticipate that there may still be a need to provide 2D plans for the purpose of stakeholder reviews and agreements.

Local and county level agencies often utilize the same software used by state agencies and are also beginning to show interest in 3D design and delivery. Projects with shared infrastructure between state agencies and municipalities present an opportunity for municipalities and their consultants to gain experience and a level of comfort in reviewing 3D models, ultimately furthering continuity across agencies and the consulting community.

Within the designer’s team and contractor’s team, subconsultants and subcontractors may not initially be equipped to deliver or use 3D. In this case, it will be important for prime consultants and general contractors to engage in the extra effort to either support their subs through mentorship and training, or in the design process take over translating the subconsultant designs into 3D deliverables. During construction, it may be necessary to convert the 3D deliverable into plan sheets and exhibits for subcontractors’ use. Any of these options may equate to additional effort and risk taken on by the prime consultant or general contractor.

Increased Survey Requirements

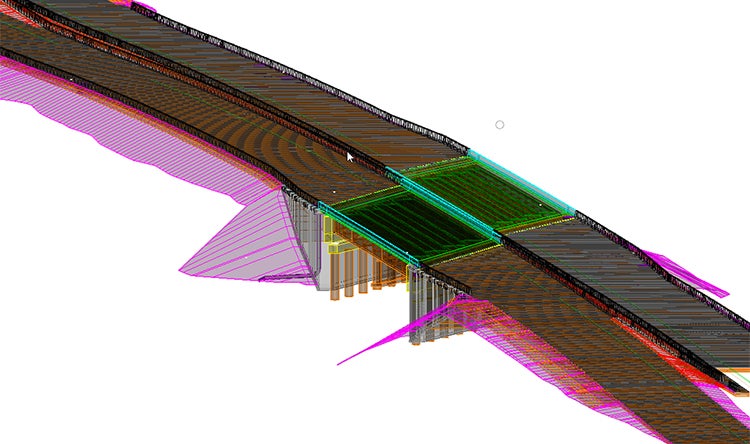

A traditional plan set may include cross sections every 50 or 100 feet, with room for contractors to interpret them in-between. A 3D model deliverable, on the other hand, can generate essentially infinite cross sections the entire length of the project. While this level of detail can anticipate problems earlier and eliminate uncertainty for contractors, it does require additional effort to produce and scrutinize during design.

Producing a contractual model deliverable suitable for Automated Machine Guidance grading and paving typically requires more data and a greater level of accuracy. This is often most noticeable at any interface between proposed design and existing conditions. For example, producing an AMG surface that has data points at construction slope limits every foot along the project requires data about the existing ground at each point. A survey that uses only 50-foot cross sections and interpolates the area in-between will lead to discrepancies between the model and existing ground. Accordingly, surveys using advanced techniques that produce a larger volume and higher density of data, such as lidar, may be required at the beginning of a project.

Regarding existing subsurface features, it may be reasonable to obtain increased quality and quantity of information on subsurface items. There are two immediate reasons for this. First, a foundational principle behind designing in comprehensive 3D is to more fully develop all of the elements within project limits. Greater transparency and communicability means the overall quality of the design can be improved and conflicts reduced between design elements and existing features. Engaging in the effort to produce detailed, high-quality 3D designs without also increasing the ability to create accurate 3D modeling of existing conditions can undermine the efficacy of producing the 3D models.

Secondly, there is a risk that modeling an existing subsurface element in 3D creates the false impression of accuracy, both for the design team, as well as the contractor in the field. The reality is that existing subsurface facilities when modeled in 3D are no more accurate than when shown in 2D; they still depend on the quality of survey or records used to establish their location.

Concurrent Industry Advancements

The adoption of 3D design and delivery should be considered in tandem with other technological shifts that are occurring in the transportation industry. Especially worth considering are the advancements in construction methods and equipment and how those advancements may impact design, construction management and asset management, within the context of 3D deliverables.

The shift to stringless paving is one example. For decades, contractors have used a string line to pave at the correct horizontal and vertical location. Stringline setters traditionally would make adjustments “on the fly” to plan grades in order to smooth out inflection points in the proposed design. This was particularly true in superelevation transitions, in order to provide improved smoothness and overall ride quality.

As deliverables shift to 3D models, in conjunction with contractors adopting stringless paving operations, superelevation design processes and standards that relied on field adjustments instead may need to incorporate adjustments for pavement smoothness and ride quality directly into the model. This may include modeling pavement at much higher interval densities to reduce chording in the final model, or running programs like FWHA’s ProVal as virtual simulation of profilograph smoothness tests.

This “direct to field use” design requires a higher level of design accuracy and can take more time and effort during the design phase to develop and quality control check the 3D data.

Another example of changing construction technology is the ability of pavement and grading equipment to record data on their operations, such as as-built surface information and compaction density information. These advances in technology are worth considering when determining how to implement 3D models into as-built records and databases.

Data Handling Concerns

More detailed models mean more data to consider. 2D CAD has long required a fully developed workspace of line-styles, colors, line-weights and more. Designing in 3D requires a larger digital workspace, with additional configurations for the display of every element in 3D space with attributes. This can include template libraries of wall types, standard material shapes, guardrails, utility conduits and more. Some of these workspaces are standardized by agencies and some can be specific to a design. Agencies will need to revise their deliverable requirements to specify the modeling and data standards required for construction and eventually for asset management.

Also important to consider is security of the data. Does every party with access to the file have adequate cybersecurity? What happens if a subcontractor with access to a model is hacked? What measures are in place to protect the integrity of the model?

Consideration should be given to how data is stored and shared, not just for the length of the project but also long term. If work is needed to update the project 20 years later, how will those future engineers and designers access the data?

Collaboration Rules

As opposed to a printed plan that is static and unchanging, a 3D file is by its nature changeable. This is a benefit of 3D deliverables, as they can be updated to reflect any changes between design and as-built versions of a project. But it also means strict care must be taken to ensure the reliability of the data through clear rules about collaboration. It is also critical to the integrity of the design product that strict rules be defined and enforced regarding any changes to the documents once the engineer signs and seals the plans.

Agencies, engineers, fabricators, contractors and others should be clear about their roles and who has access to a model, as well as their restrictions for use and changes to the model. In the same vein, some provision for tracking changes is highly recommended, so it is clear to all who changed a file, how recent that change is and what the change consisted of.

A definition of these roles should extend as long as the model is being relied upon as an accurate representation of the project, whether the project is currently being built or has already been completed.

Next Steps

Using 3D deliverables on projects is a big adjustment and not one that happens overnight. As agencies start the process, a few initial steps can help pave the way:

- Create the digital workspace needed to support 3D objectives, including a detailed level of development specification for the model that includes the intended uses, limitations and level of accuracy for all model elements. The transportation industry is starting to move to nonproprietary open 3D data standards, which should be considered with your data standards.

- Working with local ACEC and AGC chapters, create a partnering committee with consultants and contractors to identify and resolve key challenges to implement signed and sealed 3D deliverables through the design and construction process. National industry groups such as AASHTO can also provide guidance and support.

- As an initial step, require design efforts to be performed in 3D by in-house and consultant staff, with plans provided in traditional plan sheets generated directly from the 3D model.

- Provide models and electronic data files to contractors as non-contractual, for-information-only documents. This can encourage contractors to begin using the additional information to better understand the advertised contract during their bid assembly, and in the process become more familiar interacting with 3D models.

- Try pilot roadway and bridge projects with signed and sealed 3D deliverables, tracking metrics such as changes to design cost, time, construction conflicts and delays.

- BIMforInfrastructure [at] hdrinc.com (Contact HDR’s Transportation BIM for Infrastructure experts) for more information on how to begin your transition. We’d be happy to talk with you and share an update on the transportation industry movement towards 3D deliverables, lessons learned on 3D signed and sealed pilots completed to date, and the best way forward.

About the Authors

Dan Prokop: A senior transportation engineer and HDR's transportation digital delivery director, Dan has worked on highway projects of all sizes, including many of HDR’s first BIM deliverable projects.

Will Sharp: Will has three decades of experience in transportation planning, traffic engineering and highway design. A frequent participant at national conferences, he is a recognized leader in BIM adoption.