Buildings as Carbon Banks

Leveraging Design to Reduce our Carbon Impact

Recent studies indicate that in ten years or less, the world will reach a tipping point where the negative impacts of climate change are irreversible. A significant contributor to global CO2 emissions is the built environment, accounting for 45% of total emissions through the energy it uses and the carbon emitted to create it.

This carbon persists in the atmosphere for 50 to 200 years, so building emissions released now will continue to warm the climate in the future. Additionally, today’s buildings with the lowest operational carbon will still take 10 to 15 years to overcome the environmental “price” of their making due to carbon emissions associated with raw material extraction, transport, manufacturing, installation and end-of-life disposal.

How do we eliminate that price? By changing the way we think about how we design buildings.

Consider this: If we liken a building to a carbon bank, then logic follows that its components would need to sequester more carbon over their lifecycle than they emit. That means: zero operational energy design; renewable material such as mass timber and cellulosic insulation; site carbon sequestration elements such as soil building algae farming; and carbon sequestering concrete.

This new mindset dramatically changes the practice of architecture and the craft of design, most especially by requiring us to rethink the way buildings are put together so that the materials can be disassembled and reused, maintaining their carbon value. It places a larger emphasis on the entire life cycle of building and site materials, setting the stage for the building industry to move from a waste-based model to the circular economy model.

We’ve adopted an approach to carbon-balancing buildings that promises significant carbon reductions when brought to scale:

- We holistically design building architecture and engineering systems to achieve net-positive energy use. (This sounds simplistic, but 15% or 6.6 million square feet of our design portfolio is net positive ready.)

- We begin our design with the part of the building that has the largest embodied carbon footprint and remains in place the longest: the primary building structure and high performance skin. This averages about 50% of the building’s embodied carbon.

- We design every other building component in such a way that the amount of carbon emitted in this process is zero. It may sound like science fiction, but we have several projects underway where we are doing exactly that—achieving designs that sequester more carbon over their lifecycle than they emit. Currently, we anticipate accomplishing this using wood-based insulation, façade materials and interior finishes (in addition to a mass timber structure) that have a low embodied carbon content or are rapidly renewable materials that sequester carbon.

Certainly, we understand that more challenges and opportunities exist in constructing these projects. Beyond selecting materials with a lower embodied carbon intensity, we need to identify what’s needed during bidding and procurement to help projects move toward carbon neutral construction. What opportunities and sourcing challenges are specific to particular material? How can designers and contractors work to reduce carbon reductions not just in the LCA model, but in the built project? These questions are territory for continued innovation across all disciplines, industry and the public.

Carbon-balanced buildings are pragmatic and achievable using current technology.

This approach creates a distinction between the static and dynamic elements of buildings, and focuses on their stable and durable dimensions. A building’s structure and enclosure accounts for about half of its total carbon footprint. The dynamic part — mechanical systems, fixtures and finishes — is varied and changes over time, and is not part of the carbon-balanced model. But it could become integral to the equation in the future as the industry shifts to carbon banking.

A Real-Life Example in Orange County

The new administrative headquarters for the Orange County Sanitation District in Fountain Valley, California, is a good example of how a building can be designed to sequester more carbon than is emitted by its extraction, manufacture and construction. OC San is a public agency that provides wastewater collection, treatment, and recycling for approximately 2.6 million people in Orange County.

Located on a brownfield site, we worked with OC San to integrate sustainable strategies from day one in the design process, transforming them into cost-effective design drivers rather than potentially costly additions. As a civic building that serves all of Orange County, the 109,000-square-foot project is designed to be beautiful without being ostentatious and efficient while being welcoming. And as a responsible steward of their rate payers’ dollars, they required cost-effective sustainability through design decisions that deliver durable environmental performance.

Key innovative strategies that contribute to a net-zero energy/carbon neutral design (and LEED Platinum certification) include:

- Passive and active strategies for energy conservation including enhanced daylighting, high-performance envelope and high-performance building systems such as active chilled beams.

- Offset the reduced energy use with a combination of circular capture of methane from the sewage treatment to power a cogeneration plant combined with on-site PVs.

- Introducing mass timber to Southern California as a way to achieve both a lighter building and carbon sequestration.

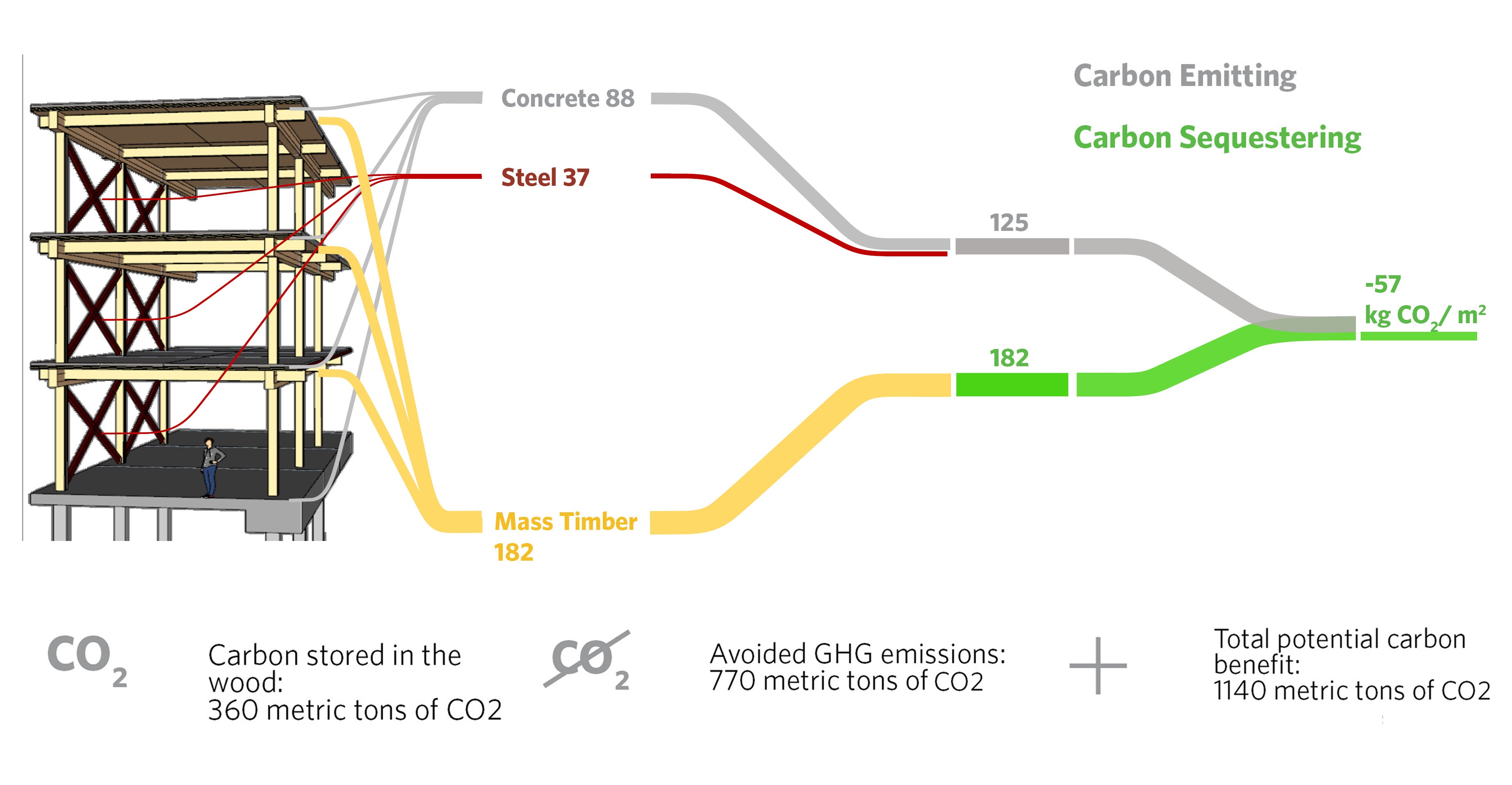

By pursuing a hybrid mass timber structure with steel lateral braces instead of the typical steel and concrete structure, the design team has addressed embodied carbon and enhanced the interior environment. The reduced weight of the building also reduced the scope of the concrete foundations thereby reducing the amount of carbon to be off-set through sequestration. Ultimately, the OC San building demonstrates that we can change the way we design and construct buildings to achieve net-zero carbon for both operational and embodied carbon.

The strength of this design solution was reinforced when we worked with our client to pursue, and win, a California Mass Timber Building Competition, which provided a grant to showcase mass timber’s viability as a change agent for structural material in commercial construction in the region.

Radically Altering Community Design Paradigms

Since this new design approach changes our fundamental thinking about long-term building operations and materials, it can also significantly impact how we plan for community development in order to support modular construction, mass timber, community carbon reduction and sustainability goals, and attainably-priced housing. At the community level, larger scales of impact can be achieved by creating opportunities for new supply chains and increased availability of resources for future projects of all types, both vertical buildings and horizontal infrastructure such as roads, bridges and water system.