Purposeful Procurement on Complex Transportation Megaprograms

Insights from Developing the Competitive Strategy for Toronto’s Ontario Line Subway

When HDR was selected as the technical advisor for Toronto’s multibillion-dollar Ontario Line project in late 2019, one of our major responsibilities was delivering an overall program schedule.

From the earliest meetings, it became clear that the initial contract approach — one large public-private partnership (P3) — was not feasible. The marketplace indicated the contract was simply too big and too risky to deliver through a single procurement by the targeted completion date, which the Ontario Line Preliminary Design Business Case published in 2020 estimated to be 2031. Continuing down that path and not fully considering marketplace feedback would have led to a failed procurement and costly delays. Instead, HDR and Metrolinx leaders thought creatively about the program’s structure and packaging, dividing it into multiple projects managed through a central management team.

Working with subway owners Metrolinx and Infrastructure Ontario, our team undertook extensive work to determine what approach should be used for each part of the 15.6-kilometer alignment. The resulting procurement approach for the transformative downtown subway extension eventually grew to include 28 separate contracts using multiple contract approaches, all driven by the goal of completing the work on schedule. Detailed sequencing and meticulous coordination led to an overall program designed to deliver this important piece of infrastructure to Toronto’s residents.

The Contracts

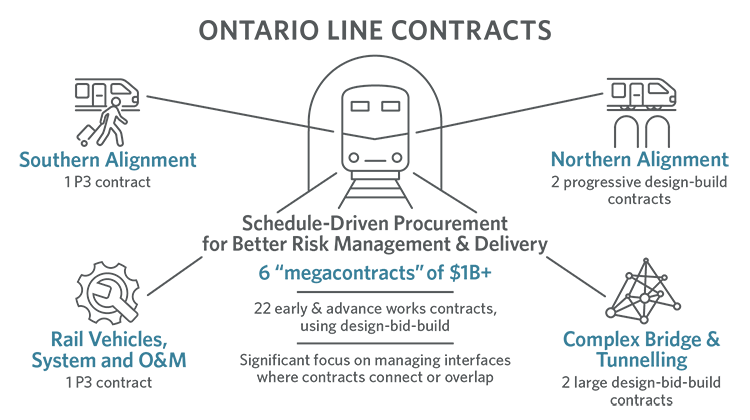

The Ontario Line is now being delivered through a mix of contract approaches:

- 2 P3 contracts — one for the southern downtown and underground civil portion of the alignment and another covering the rail vehicles, systems and 30-year O&M contract for the entire alignment.

- 2 Progressive design-build (PDB) contracts for the northern part of the alignment, one for the at-grade and tunnel section and one for the elevated guideway section.

- 2 Large design-bid-build (DBB) contracts issued to keep complex bridge and tunnelling portions of the program on schedule

- 22 Early and advance works contracts initiated as DBB contracts to move utilities and commuter rail tracks

Determining what methods to use and the right combination can be challenging, but based on the Ontario Line and our work on other megaprograms across North America, HDR has identified a number of best practices to keep programs on schedule, reduce risk and improve program efficiency:

Consider Schedules and Risk Factors Early

When program efficiency is important, exploring construction sequencing and program schedules earlier is critical. Setting budgets and deadlines without the right analysis can lead to picking delivery methods and timeframes that instead compound risk. On a recent transit project in the U.S., for instance, leaders realized too late that a CM/GC method would have been more useful. But procurement takes time and the opportunity was missed.

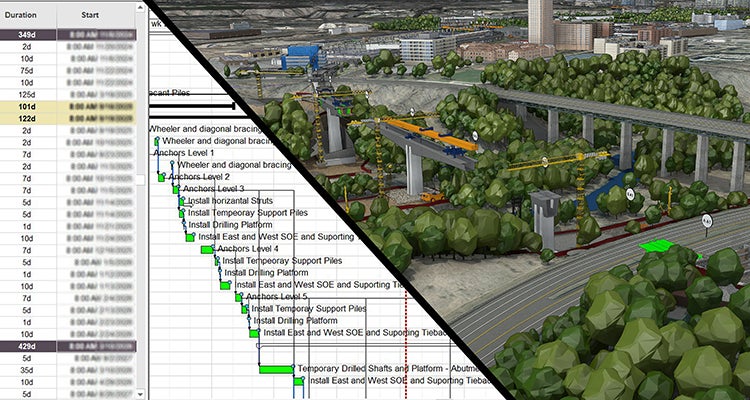

It’s tempting to spend early work thinking about technical aspects while making assumptions about delivery method or phasing. But waiting too late to think about a procurement strategy can lead to missed opportunities to mitigate risk, and to inform cost and scheduling. Instead, engaging construction scheduling, planning and cost estimating teams early in the process can identify opportunities to improve program schedules. On the Ontario Line, this meant talking to experts at the concept design stage to determine what was feasible, including detailed constructability and scheduling analysis of projects to help inform method selection and phasing.

A systems engineering approach that considers operational requirements up front can also aid in this effort. On the Ontario Line, the expectation was set early that trains run as frequently as every 90 seconds during rush hour. Understanding that requirement led to a decision to implement a driverless Grade of Automation 4 (GoA4) system, the only feasible solution for creating a system with a 90-second headway. That in turn led to other requirements, including a dedicated guideway that isn’t shared with other traffic. And understanding all of these requirements led to a decision to procure the systems elements earlier than normal to allow time to develop what will be a complex system.

On the Ontario Line, contract approaches were considered carefully to match different needs of the massive project. Work on the northern alignment was originally advanced with the idea of using a DB contract, for instance. But it became clear that one station in particular would be much more complicated and because it was on a critical path, it could risk delays to the overall program schedule if packaged with all the other stations. It also required third party approval that could lead to schedule challenges. As a result, the design of that station was pulled out into a separate DBB contract that provided Metrolinx more design control and allowed the complex design to be advanced and reviewed while procurement for other work was completed using a larger PDB contract. Recognizing this complication early in the process allowed the program to explore different procurement approaches and shift strategy to better match the overall schedule.

Embrace the Variety of Delivery Methods Available

Large, complex programs have complex needs, so it makes sense that different delivery methods would work better for different sections of a program. The reality is that megaprograms rarely remain as one large contract. There will always be early works projects or other parts of a program that make sense to complete separately from a main contract. Determining which projects can be better served through separate contracts because of risk or schedule is an important part of program success.

As described above, while the Ontario Line began with the idea of one large P3 contract, it eventually became 28 contracts, including six megacontracts and 22 supporting contracts, all of which have been let. The change was made in response to risk concerns, schedule, the local construction market, financial markets and what made sense from a packaging standpoint. In just one example, the decision was made to use a DBB approach on a major signature bridge on the project because it includes challenging interfaces and third party coordination and approvals with work to the south and north. A DBB allowed more design control to manage those interfaces.

The popularity of delivery methods can also flex and change. For instance, the favorability of P3s fluctuates as private borrowing rates rise and fall. PDB is seeing increased popularity at the moment largely because of the risk of fixed-price bidding based on preliminary engineering. Allowing the design to progress further holds the promise of better cost and schedule certainty.

When considering delivery methods, it's also important to understand the timing of other major programs in the area, which can affect availability of contractors and design staff. And owners should consider whether local contractors and owners are familiar with the delivery methods being pondered. In Toronto, Infrastructure Ontario has significant experience and familiarity with alternative delivery options, which makes it a strong partner in overseeing different contractor approaches and contributing to the procurement strategy. But that’s not the case in many other locations, and sometimes it can be a heavy lift to educate all parties on the intricacies of newer delivery methods.

Use Schedule and Scope to Drive Contract Decisions

Determining how to split a program into specific contracts begins with knowing the schedule drivers and scope for each part of the program. For example, perhaps one contractor involved is very good at building bridges, another at building tunnels — that provides a natural split of scope. With transit in particular, rail car and systems providers are not known to be strong on the civil side of delivery and this creates a natural split if systems and operations and maintenance (O&M) are also needed. On top of that, consider the complexity of the work to decide what procurement option is best. A simple bridge that wouldn't benefit from a lot of innovation might prompt a decision to use a traditional DBB approach. But if there's opportunity for optimization, innovation, or it’s highly complex, then alternative delivery could be better suited.

Breaking a program into multiple projects and contracts can also help spread out risk and improve schedules. Consider a situation in which advance works projects are struggling to secure permits and approvals. If these are part of one single program contract, that can be a major problem with a large impact to overall schedule and potentially leading to expensive claims. But if they’re part of separate projects, problems can be dealt with individually instead of holding up the whole program.

Pay Close Attention to Contract Interfaces

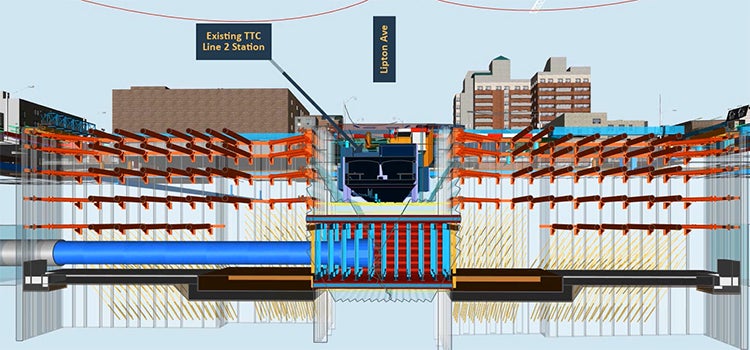

In megaprograms with multiple major contracts, managing the contract interfaces is also critical to maintaining schedule and reducing risk.

During procurement, owners should make sure technical specifications align between contracts. Be clear about the limits of design and the leeway that an owner has to force a solution if an issue arises between two contracting parties. The goal is to make sure that designs by two private parties both fit the overall program needs.

On the Ontario Line, interfacing has been a significant area of focus, particularly because there is an overlay of a systems contract on a civil contract. The train system and the infrastructure it will run on are being designed through separate contracts. It’s critical that they work together.

We have seen challenges with interfacing on other programs, when a proper analysis of space and time needed for separate contracts was not completed. When work on one contract overlaps unexpectedly with another scheduled to take place at the same time and in the same place, it can lead to costly change orders and schedule delays. To reduce the chance of this, the Ontario Line team put a lot of effort into schedule and space-proofing on contracts, with independent reviews and input from the contracting industry. Construction planners were an active part of daily work as the program progressed. Including their expertise and analysis helped to define the design, by informing the team on constructability, schedule, cost and risk.

Procurement Strategy Is Integral to Success

Successfully planning a megaprogram requires paying attention to a host of details. But it’s important to keep focus on the delivery — schedule, construction means and methods, cost, and risk — as much as on planning and design. For those embarking on the early stages of a program, three tasks stand out as critical:

- Know the market — what is the consulting and construction industry’s experience with different delivery models?

- Know the procurement owner’s ability to manage multiple projects and multiple delivery methods simultaneously.

- Know the delivery plan — invest in due diligence focused on cost, schedule and risk.

Combined with an early commitment to prioritize procurement strategy, these items will provide a strong foundation for the many decisions that will follow. As the Ontario Line program shows, the decisions can be complex and require weighing many options. But a clear focus on the top priorities will provide clarity and help guide decisions toward a successful procurement process.