Reuniting Communities in Uganda

This article was originally published in Bridge Design & Engineering magazine's Q2 2025 issue (subscription required), titled “Communities Reunited.” Republished here with permission. Images courtesy of Engineers Without Borders.

Engineers Without Borders Partners with HDR to Build Long-Span, Hybrid Suspension-Suspended Pedestrian Bridge in Remote Western Uganda

By Rick Fauteux, Robert Mateega and Michael Roberts

Nestled in a picturesque and remote valley carved by the shifting and powerful Mubuku River, the communities of Nyakabuha and Bikone in the Kasese District of western Uganda experienced extreme flooding five years ago.

In the early rainy season of 2020, a surge of water and boulders came crashing down from the nearby Rwenzori Mountains, devastating a critical pedestrian bridge, damaging a school, hospital and homes as well as severing other shorter bridges connecting the villages nearby.

Residents were faced with a 2.6-kilometer detour to the nearest bridge, a vehicular crossing, or with using dangerous log bridges susceptible to washouts. The communities desperately needed a resilient bridge for the safety and livelihood of more than 1,000 residents.

As of some months ago, however, thanks to the support of a volunteer team formed by Engineers Without Borders and global professional services firm HDR, the two communities are now reconnected by the Nyakabugha-Bikone Pedestrian Bridge, the longest footbridge in the country.

EWB had previously collaborated with these Ugandan communities, recently building drinking water stations for them, and had backing from an assortment of local entities including public agencies, a surveyor, a geotechnical firm, community groups and stakeholders, while financial support for construction was secured from a private donor. The technical support was provided by HDR, who provided 22 volunteers from 18 of its US offices to work with Nyakabuha and Bikone community leaders, Kasese District officials, the Uganda National Roads Authority and non-profit charity Bridges to Prosperity.

The all-volunteer HDR team provided the critical expertise needed to develop construction plans for a new resilient pedestrian bridge.

As well as local community engagement, the project required hydraulic and hydrologic modelling to determine the appropriate bridge deck parameters for elevation and length, necessary scour protection, and bridge design services. For regional best-practice in bridge design, material procurement and construction, the team consulted with B2P, who was also already active in the area.

A key part of the team’s call to action for this ambitious bridge was engaging engineers familiar with long-span, cable-supported structures; simple trail bridges; and basic construction methods necessary to build in a remote location.

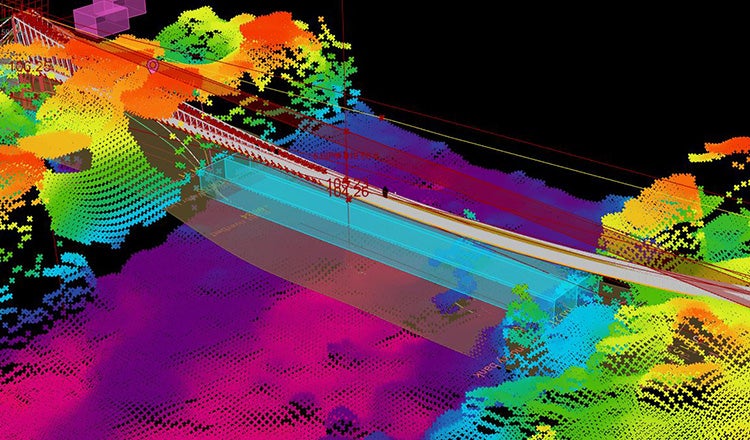

HDR project manager Rick Fauteux assembled a group that could address the wide range of challenges and skill sets needed. With limited geographic information and site survey data available, HDR hydraulics manager Dan Pfeifer led the development of a watershed model with the required geometric parameters and aerial imagery donated by an aerospace company. Michael Roberts, an experienced cable-supported footbridge HDR engineer, worked with the aerospace company to refine the aerial imagery and create a 3D model of the site terrain.

Once the raw satellite colour bands had been processed and combined using geographic information system tools, a highly detailed surface mesh of the project site could be integrated into the digital geospatial model improving site resolution. Combined with an innovative form-finding model of the bridge, this digital model improved site-specific insights and offered an even more accurate canvas for layout and placement of the bridge within its actual environment.

Robert Mateega, who was born in Uganda and served as HDR’s bridge design lead, guided a team of engineers, computer-aided drafting technicians and modelers to develop the bridge alternatives. Wendy Thompson, HDR community engagement manager, led the team’s public outreach efforts by creating meeting display materials and handouts both in English and in Lukonzo, the local language.

A key design consideration was the project area’s susceptibility to flash flooding and large flowing debris in the river. Initially, a vehicular bridge with sidewalks was planned. However, an initial site visit in February 2022 revealed that a span of at least 80m would be required to keep bridge substructure elements out of the river and avoid destructive debris during the rainy season.

As the cost and design effort for a vehicular bridge was too high for a private donation and the design team working pro bono, the project team selected a pedestrian bridge.

Two potential bridge locations were revealed by an initial visit, and the project team was able to leverage the 3D aerial mapping of the two sites and environs to assess locations for hydraulic analysis. The modelling subsequently identified a potential third location, close to one of the initially identified locations, as the ideal bridge site. This sat on a straight alignment with reduced potential for lateral migration of the river or bend scour on the abutments. It also featured a massive, approximate 9 meter by 9 meter boulder on the north bank, which provided natural scour protection to the structural elements on that bank.

The project team worked with a basic line survey and geotechnical information obtained by EWB to develop two proposed conceptual options for the bridge. HDR’s Roberts matched the survey information to the 3D aerial imagery and confirmed the data points with drone imagery obtained in later visits. Both options included a hybrid suspension-and-suspended-style bridge with a metal walkway, one 106 meters in length and the other 84 meters.

Once the two conceptual-level alternatives had been developed, it was time to present them to the local community. In March 2023, Mateega travelled to Uganda with display materials in both English and Lukonzo (Local dialect/language). Together with EWB staff, three meetings were held with Kasese District officials, the Uganda National Roads Authority and the local community. The materials proved invaluable in helping the participants understand the alternatives being proposed and, ultimately, collaboratively decide on the preferred option – the 106-meter-long bridge, which featured a difference in elevation of 3.86 meters between proposed substructure element locations on either bank.

The participants favoured this option because it featured substructure elements further away from the river and, as one member of the community commented: “We want the bridge to be as high as possible above the river, as we have seen entire trees come floating down the river during flood events.” In this preferred option, the south abutment was placed as far away as possible from the river without encroaching on nearby structures, while the north abutment was placed on a ledge above potential flood waters.

Additional factors taken into consideration included a recommendation by EWB that the structure be designed with locally sourced materials to boost the local economy and in consideration of future maintenance needs.

The hybrid-type bridge was selected to account for and take advantage of the elevation change between abutments. It features a suspension tower on a 4.48-meter pedestal at the south abutment and a concrete and masonry tower that provides a 1.5-meter vertical at the higher ground of the north abutment.

While the suspended tower on the north could be entirely constructed with material readily available around the project area, the suspension tower at the south required fabrication of steel members in the country’s capital city, Kampala, located about 230 miles to the East.

Importantly, the hybrid structure would provide 3 meters of vertical clearance between the highest water elevation observed by the community and the bottom of the walkway.

The required geometrics for this bridge fell outside of the prescriptive B2P details and necessitated a bespoke analysis. The two alternatives were developed using Grasshopper and Rhino3D CAD software, along with guidance from the B2P design manual. The software took into consideration the bridge’s nonlinear behaviour, and the results confirmed that the bridge’s deflected shape was above the critical vertical clearance.

The software was used to develop custom-scripted tools that could address conventionally complex, time-consuming, nonlinear geometric analysis made more challenging by the hybrid elements and behaviour of the bridge. The tools expedited and optimised efforts to determine initial geometric conditions for the structural analysis before finalising the design in conventional structural analysis software.

The ability to make key geometric changes, modify loading or boundary conditions and receive almost instant response was a powerful form-finding innovation which significantly improved final design efforts and outcomes. This was especially true because the geometry was nonuniform and asymmetrical, with 3D effects that directly influenced the structure's large vertical displacement response.

The final geometry, determined through the form-finding process at both the unloaded and loaded geometries, was then relied upon to establish key geometry and to produce the final CSiBridge model, which was used to produce the official force and deformation results for design.

The digital topography model and the final parametric geometric form used for final design followed the form-finding exercises that set all the key elevations – for example saddles and deck — and provided the critical geometry for the final analysis model in CSiBridge.

The B2P design manual recommends a live load of 4.07kN/m2 but applies a reduction if the bridge deck area exceeds 37m2. As a result of the bridge’s deck area, this resulted in the minimum of 3.14kN/m2 being applied and is a reduction representing the reduced probability that the entire bridge would be fully loaded simultaneously.

The analysis determined that three 32-millimeter-diameter cables per side of bridge were required. A factor of safety of 3 and 5 was used for the mainline cables and hangers, respectively.

Final plans for the bridge were submitted in January 2024, and construction on the project began in March 2024 with the building of an access road to the site. A temporary bridge was also built to get construction material, equipment and personnel across the river. Finally, a shed to house construction material, a construction office, a kitchen and on-site security offices was built as part of site preparation.

The temporary bridge immediately validated the need for the new bridge, as the community immediately started using the temporary bridge, including school children and so-called boda bodas (for-rent motorcycles) used to transport people and goods.

Bridge construction was performed by a project contractor assisted by both skilled and unskilled community members, EWB construction staff, HDR volunteers and community volunteers. The project contractor provided a project consultant, Samuel Mukasa, who had experience building similar suspension and suspended bridges in Uganda with B2P. The project contractor also consisted of a project foreman and two masons, all of whom had worked on prior B2P bridge builds.

Working on the project provided community members with employment. The skilled community members had experience working in construction but not necessarily in bridge construction. The unskilled community members had no prior construction experience. Most community members were subsistence farmers.

The project also served as a way to teach new skills to community members, such as measuring and bending reinforcement bars and using power tools. They also learned masonry skills from the two skilled masons on the project. Working on bridge construction gave the community members more ownership of the project, as they appreciated the skill and effort required to build the bridge. This experience will help them maintain the bridge over its expected 75-year design life.

The EWB construction staff members were present every day and provided construction oversight, procured construction material and paid community members for their work. In August 2024, HDR senior bridge CAD technician Eric Sorens accompanied Mateega to volunteer with the bridge construction, and they were warmly welcomed by the local community. The two volunteers spent 10 days on the site, during which they backfilled the south ramp with rock and grout, poured concrete for the south ramp slab, cut and bent hangers, installed scaffolding for raising the steel tower, observed the tower raise, tightened and adjusted cable, and launched hangers and crossbeams for the walkway.

In laying out the bridge, it was known that there were large boulders buried in the south bank, and the bridge was laid out to try and avoid these boulders. But, as the south abutment ramp and anchor were excavated, additional large boulders were encountered, and the boulders got larger with deeper excavation. Initially, these were removed by hand using cables and ramps made from logs, but they became so large that heavy machinery from the Kasese District was brought in to ease removal. This was the only heavy machinery used on the project — everything else was constructed by hand or with hand tools.

An extraordinarily large boulder was encountered close to the edge of the south abutment anchor. It would have required extending the excavation limits laterally and vertically to expose the entire boulder for removal by heavy machinery. Consequently, it was decided to leave it in place, and the south abutment anchor was redesigned.

A high water table was also encountered at the south anchor location, something that had not been identified in the limited geotechnical investigation performed at the site. This issue required the team to quickly redesign the south anchor to account for buoyancy from the high water table.

The three 32-millimeter-diameter cables required on each side of the bridge were challenging to install. There was no accurate way to measure the tension in the cables on site due to the basic pulley system used, other than having the low point of the cable profile under self-weight matching the low point determined by calculations. It was extremely time-consuming to get all three cables on each side to match this elevation. Most B2P bridges only have two cables on each side. The cables were initially raised above the target elevation by tensioning the cables with a pulley system and then lowered by releasing and loosening the cable clamps and striking the cables with timber posts to release their tension.

In September 2024, six months after starting, major construction of the bridge was completed and the bridge was opened to the public. In February 2025, the official dedication ceremony was held, with Dr. Engr. Patrick Rusongoza, from the office of the president of Uganda, attending as the guest of honour. The ceremony was attended by representatives of the private donor as well as EWB, HDR, B2P, Kasese District officials, the Uganda National Roads Authority, and community leaders and members. The dedication featured traditional dancers and music by the local communities.

Now, through various conditions on the Mubuku River, residents can stay connected thanks to the new Nyakabugha-Bikone Pedestrian Bridge. Children can access schools all year round, and parents can take comfort that they have a reliable way to cross the river. Residents can access health care facilities and markets, and they can visit each other on foot or on boda bodas. Subsistence farmers can expand their commercial crops, with year-round access to markets, growing the local economy.

These renewed connections were made possible through stakeholder collaboration, community engagement and engineering innovation for a resilient river crossing. For the volunteer design team, this was an opportunity to use technical skills to provide a positive, generational impact for two communities in need.

About the Authors

Rick Fauteux is bridges and structures program delivery leader at HDR. Robert Mateega and Michael Roberts are senior bridge engineers at HDR.